To maintain your booster pump, regularly inspect the pump and its components for wear, leaks, or damage. Check and replace filters as needed, and monitor pressure and flow rates to catch issues early. Keep moving parts lubricated and tighten loose fittings to prevent leaks. Clean the pump and surroundings often, and schedule routine maintenance. Address common problems promptly to keep your pump running smoothly—continue to learn more about effective maintenance techniques.

Key Takeaways

- Regularly inspect and clean pump components, including the impeller, casing, and fittings, to prevent debris buildup and leaks.

- Schedule routine filter checks and replacements every 3-6 months to maintain optimal flow and pressure.

- Lubricate moving parts and bearings as per manufacturer instructions to reduce wear and extend pump lifespan.

- Check electrical connections, wiring, and circuit breakers regularly for safety and proper operation.

- Monitor system performance through gauges and flow data, addressing pressure drops or irregularities promptly.

Top picks for "maintain booster pump"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

Inspecting the Pump and Its Components

To guarantee your booster pump operates efficiently, you should regularly inspect the pump and its components. Start with the pump casing, ensuring there are no cracks, corrosion, or leaks that could affect performance. Next, focus on the impeller inspection; check for signs of wear, damage, or debris buildup that could reduce flow or cause imbalance. Removing the pump cover allows you to access the impeller easily. Clean it thoroughly, removing any stuck debris, and verify that it spins freely without excessive play. Inspecting these parts regularly helps catch issues early before they cause larger problems or damage to other components. Keeping the pump casing and impeller in good condition ensures excellent operation, longevity, and reduces the risk of unexpected breakdowns. Regular maintenance also includes monitoring filtration, which protects the pump and extends its lifespan. Incorporating preventative maintenance practices can further improve reliability and performance over time. Additionally, checking for proper lubrication of moving parts can prevent unnecessary wear and extend the life of your pump. Incorporating component inspection is essential for identifying early signs of deterioration and avoiding costly repairs. Implementing proper troubleshooting methods can help identify issues quickly and minimize downtime.

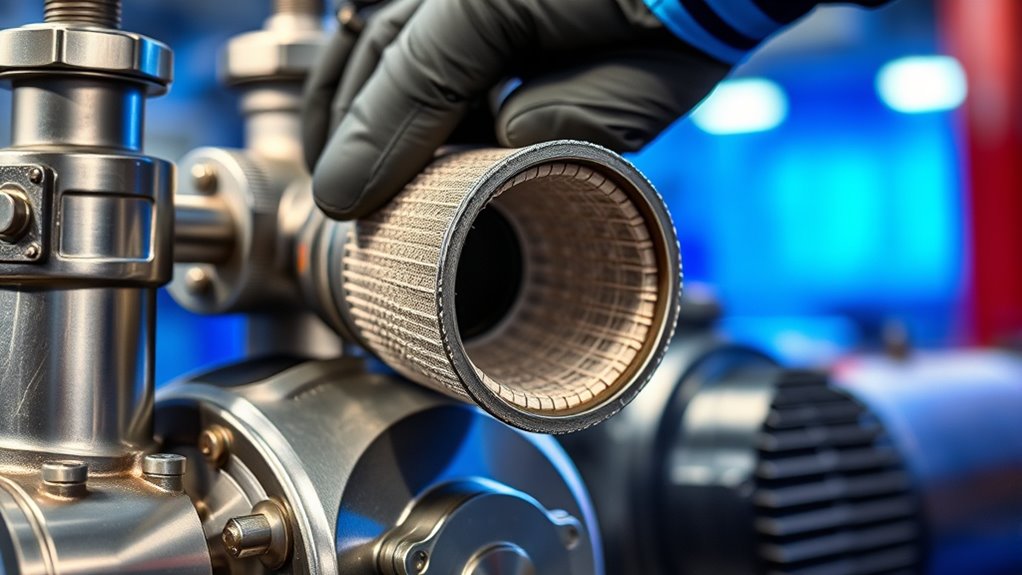

Checking and Replacing the Pump’s Filter

Regularly inspect the filter to make certain it isn’t clogged or dirty. If it looks dirty, clean or replace it promptly to keep your pump running smoothly. Make sure you’re using the correct filter type for your system to prevent issues down the line. Incorporating literary humor into maintenance routines can make the process more engaging and less tedious. Additionally, staying aware of AI vulnerabilities can help you better understand potential risks in automated systems, ensuring your equipment remains safe and reliable. Recognizing vibrational energy in your maintenance approach can also support a more positive and effective upkeep routine. Being familiar with cake pop decoration tools can inspire creative ways to improve your maintenance setup, making routine checks more enjoyable. Understanding automation’s role in business intelligence can also help you appreciate how automated insights contribute to operational efficiency, even in maintenance tasks.

Inspect Filter Regularly

How often should you check your booster pump’s filter? Regular inspections help prevent clogs and guarantee ideal performance. You should inspect the filter at least once every three to six months, depending on usage and water quality. During each check, look for signs of buildup, debris, or damage. If the filter appears dirty or clogged, it’s time for a filter replacement. Proper disposal of the old filter is essential to avoid environmental harm. Always follow local disposal regulations when discarding filters. Regular inspection helps you catch issues early, saving you money in repairs and maintaining water flow efficiency. Additionally, understanding filter maintenance can help you identify potential problems before they affect your booster pump. Being aware of Vetted – Flat Iron Bike features can also inform you about reliable components that may be used in some pump systems. Remember, consistent filter checks contribute considerably to your booster pump’s longevity and reliable operation.

Clean or Replace Filter

When you notice your filter is dirty or clogged during inspections, it’s time to clean or replace it to maintain peak performance. Ignoring this can reduce your pump’s efficiency, increase energy costs, and shorten the filter’s lifespan. Regularly checking and adhering to your filter replacement schedule keeps your system running smoothly. Monitoring your performance cookies helps you understand how well your system is functioning and when maintenance is needed. Ensuring your filter’s proper filtration system is crucial for optimal operation and longevity. Incorporating automation technologies such as machine learning can also help predict when maintenance is required, preventing unexpected failures. Additionally, using durable inlet strainers can prevent debris from clogging the filter, further safeguarding your equipment.

Use Correct Filter Type

Ensuring you use the correct filter type is vital for your booster pump’s ideal performance. Proper filter selection guarantees compatibility with your pump model and prevents damage or inefficiency. When choosing a filter, refer to the manufacturer’s specifications to determine the right type and size. Using an incompatible filter can cause clogging, reduce flow rate, or lead to pump failure. During filter installation, make sure it’s seated correctly and securely to prevent leaks and guarantee optimal filtration. Always follow the manufacturer’s instructions for installation and replacement intervals. Regularly checking your filter and replacing it with the correct type helps maintain consistent pressure and prolongs your booster pump’s lifespan. AI-driven solutions are increasingly influencing how maintenance and monitoring are performed, helping to optimize pump performance. Implementing energy efficiency ratings in your selection process can further enhance system performance and reduce operational costs. Additionally, paying attention to filter maintenance guidelines ensures your system remains effective and extends the life of your pump. Taking these steps ensures your pump operates smoothly and efficiently.

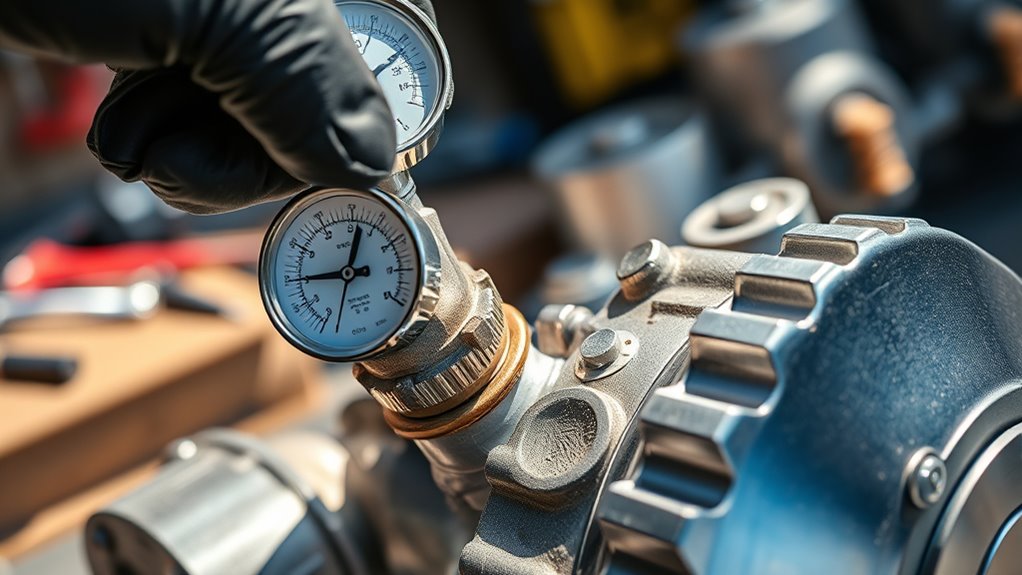

Monitoring Pump Pressure and Flow Rate

Monitoring pump pressure and flow rate is essential for maintaining ideal booster pump performance. By keeping a close eye on these metrics, you can detect early signs of pressure fluctuations that might indicate issues. Consistent flow ensures your system runs smoothly and prevents unexpected shutdowns. Regularly check your gauges and record readings to spot trends and respond promptly. If you notice pressure drops or irregular flow, address the problem immediately to avoid damage. Staying vigilant helps prolong your pump’s lifespan and keeps your water supply reliable. Remember, proactive monitoring is the key to avoiding costly repairs and guaranteeing peak operation.

- Feel confident knowing your system is running at peak efficiency

- Avoid sudden breakdowns that disrupt your daily routine

- Protect your investment by catching issues early and acting swiftly

Lubricating Moving Parts Regularly

Regularly lubricating the moving parts of your booster pump is vital for maintaining smooth operation and preventing unnecessary wear. Check the oil levels regularly to guarantee they stay within the recommended range, topping up as needed. Proper lubrication reduces friction and minimizes the risk of parts seizing or overheating. Apply grease to bearings and other designated components according to the manufacturer’s instructions. Use the correct type of lubricant to avoid damage and ensure ideal performance. Make it a habit to inspect lubricant application points during routine maintenance. Proper lubrication not only extends the life of your pump but also keeps it running efficiently. Consistent attention to oil levels and grease application is a simple yet essential step to prevent costly repairs and downtime.

Examining Electrical Connections and Wiring

To keep your booster pump operating safely and efficiently, you should examine the electrical connections and wiring regularly. Check the ground wire to ensure it’s secure and undamaged—this is crucial for safety. Inspect the circuit breaker to confirm it hasn’t tripped and that it matches the pump’s power requirements. Look for loose or corroded connections that could cause malfunctions or hazards. Address any frayed wires immediately to prevent shorts or electrical fires. Keeping these connections tight and in good condition protects your equipment and your safety. Don’t ignore warning signs like flickering lights or unusual noises, as they may indicate wiring issues. Regular inspection gives you peace of mind and extends your pump’s lifespan.

- Feel confident knowing your connection is safe and reliable

- Avoid costly repairs caused by overlooked wiring issues

- Protect your home and loved ones from electrical hazards

Testing the Pump’s Performance

To guarantee your booster pump is working properly, you should check the flow rate and monitor pressure levels regularly. These measurements help you identify any performance issues early. By paying close attention to these points, you can keep your pump operating efficiently and avoid unexpected failures.

Checking Flow Rate

How can you guarantee your booster pump is performing correctly? Checking the flow rate is essential. Start by verifying flow rate calibration using a flow meter, ensuring it matches your pump’s specifications. Also, double-check the pressure gauge accuracy, as faulty gauges can mislead you about performance.

To confidently assess performance, focus on these key points:

- Consistently measure flow rate and compare it to baseline data

- Ensure pressure gauges are properly calibrated

- Watch for sudden drops or irregularities in flow

Monitoring Pressure Levels

Monitoring pressure levels is a vital step in ensuring your booster pump operates efficiently. Regularly check for pressure fluctuations, which can indicate issues like valve problems or blockages. Use a reliable pressure gauge to track readings and spot irregularities early. It’s also important to verify that your sensors are properly calibrated; inaccurate sensor readings can mislead your assessments. Periodically calibrate sensors according to the manufacturer’s instructions to maintain accuracy. Keep an eye on pressure trends over time, not just single readings, to detect subtle changes that may signal a problem. Consistent monitoring helps you catch issues before they escalate, ensuring your pump maintains maximum performance and prolongs its lifespan.

Cleaning the Pump and Surrounding Area

Have you ever overlooked the importance of keeping your booster pump and its surrounding area clean? Dirt and debris around the pump housing can cause overheating, blockages, and reduce efficiency. Regular cleaning guarantees your system runs smoothly and prolongs its lifespan.

- Prevent unexpected breakdowns that leave you stranded

- Protect your investment from damage caused by debris buildup

- Ensure safe operation and peace of mind

Start by turning off the pump and removing any surrounding debris carefully. Wipe down the pump housing with a damp cloth to remove dirt and dust. Keeping the area clean not only improves performance but also helps you spot issues early, saving you time and money in the long run.

Tightening Loose Fittings and Bolts

Loose fittings and bolts can cause significant issues if not addressed promptly. When you notice any leaks or vibrations, it’s time to check and tighten the fittings and bolts. Start by inspecting all connection points for looseness. Use a wrench to tighten bolts securely, but avoid overtightening, which can damage components. During this process, if you see signs of wear or deterioration, consider seal replacement to prevent leaks. Proper bolt tightening ensures the pump operates efficiently and reduces the risk of damage. Tightening loose fittings also helps maintain proper pressure and flow. Regularly checking and securing these connections is a simple yet effective way to keep your booster pump running smoothly and prolong its lifespan.

Scheduling Routine Maintenance Checks

How often should you schedule routine maintenance checks for your booster pump? The key is establishing a consistent maintenance schedule based on the manufacturer’s recommendations and your pump’s usage. Regular inspections help prevent unexpected failures and extend your pump’s lifespan. Set a clear inspection frequency—monthly, quarterly, or annually—depending on your operation’s demands.

Establish a regular maintenance schedule based on manufacturer guidelines and usage.

Remember, sticking to this schedule can evoke peace of mind, knowing your system is reliable. It also helps you catch small issues before they escalate, saving you money and downtime.

- Catch problems early and avoid costly repairs

- Ensure peak performance and efficiency

- Protect your investment and peace of mind

Troubleshooting Common Pump Issues

Regular maintenance checks help keep your booster pump running smoothly, but issues can still occur despite your best efforts. If you notice unusual pump noise, it often signals a problem like cavitation or worn bearings. Vibration issues may indicate misalignment, loose mounting, or imbalanced components. Start by inspecting the pump for any signs of wear or damage. Tighten loose bolts and ensure the pump is properly aligned. If noise persists, check for debris or buildup that could be causing imbalance. Vibrations that continue after adjustments may require professional inspection to identify internal issues. Addressing these problems promptly prevents further damage and keeps your system operating efficiently. Regularly monitoring your pump allows you to catch issues early and maintain excellent performance.

Frequently Asked Questions

How Often Should I Replace My Booster Pump Entirely?

You should replace your booster pump based on a proper replacement schedule, typically every 5 to 10 years, depending on usage and condition. Regular pump maintenance helps identify signs of wear early, preventing unexpected failures. If your pump shows persistent issues like reduced pressure, strange noises, or frequent breakdowns despite maintenance, it’s time for a full replacement. Following a consistent replacement schedule guarantees maximum performance and longevity of your system.

What Are Signs of Imminent Pump Failure?

You’ll notice signs of imminent pump failure if you hear unusual pump noise or experience vibration issues. These sounds and vibrations often indicate worn bearings, cavitation, or imbalanced components. If your pump starts making grinding or humming noises or vibrates excessively, it’s a warning to check it promptly. Addressing these signs early helps prevent complete failure and costly repairs, ensuring your booster pump continues functioning efficiently.

Can I Upgrade My Pump for Better Efficiency?

Imagine the thrill of upgrading your pump for better efficiency—sounds enticing, right? You can definitely explore efficiency upgrades, but first, assess your current pump’s condition through proper pump maintenance. Upgrading might involve installing a more advanced model or optimizing your existing system. Just guarantee you weigh the benefits against costs and compatibility. With the right approach, you’ll boost performance and save energy—making every drop count.

Is It Necessary to Calibrate the Pump Regularly?

You might wonder if regular calibration is necessary for your pump. To guarantee ideal pump accuracy, it’s recommended to calibrate it periodically. Calibration frequency depends on your usage and environment, but generally, checking it every few months helps maintain accuracy. Regular calibration prevents performance issues, saves energy, and prolongs your pump’s lifespan. So, yes, staying consistent with calibration is essential for reliable operation and efficient performance.

How Do Environmental Factors Affect Pump Lifespan?

Ever wondered how the environment wears down your pump over time? Environmental factors like moisture impact and corrosion resistance play big roles in its lifespan. Excess humidity speeds up rust and corrosion, weakening components. Poor corrosion resistance makes your pump vulnerable to damage, reducing its efficiency and longevity. To protect your investment, guarantee proper sealing and choose materials with high corrosion resistance. Keep an eye on environmental conditions to extend your pump’s life.

Conclusion

Regularly inspecting, checking, monitoring, lubricating, examining, cleaning, tightening, scheduling, and troubleshooting keeps your booster pump running smoothly. Staying proactive ensures efficiency, prevents costly repairs, and extends the pump’s lifespan. By giving attention to each step, you maintain peak performance, avoid unexpected breakdowns, and save time and money. Keep up with your maintenance routine, stay vigilant, stay consistent, and enjoy reliable operation day after day. Your pump’s dependability depends on your dedication.