To create a robot vacuum cleaner, start by selecting components like Arduino, sensors, a strong chassis, and motors. Opt for durable materials such as acrylic or aluminum for the chassis, include support beams, and carefully position motors for efficiency. Connect the components according to a circuit diagram, set up sensors for detection, and utilize a motor driver for precise control. Strategically place sensors for obstacle detection, incorporate ball casters for smooth movement, and integrate bumpers for accurate collision prevention. Program the robot using Arduino IDE for independent cleaning. Thorough testing is key to ensure reliability. For more details on the design process, check out this link: Robot vacuum cleaning tips. Make sure the robot vacuum cleaner’s brush and suction systems are optimized for efficient debris collection. Also, consider adding a dustbin with a suitable capacity and efficient battery management for extended operation. Regular maintenance, including cleaning sensors and brushes, is crucial for optimal performance. In creating a simple robot vacuum cleaner, focus on maximizing battery life and debris collection efficiency. Implement a virtual wall system to limit the cleaning area and set up a docking station for automatic recharging. Consistent maintenance and cleaning of components will enhance the longevity and effectiveness of the simple robot vacuum cleaner.

Key Takeaways

- Choose durable chassis material like acrylic or aluminum.

- Optimize sensor placement for obstacle detection.

- Implement ball caster for omnidirectional movement.

- Program Arduino for autonomous navigation.

- Test thoroughly for reliable operation.

Materials Required

To design a robot vacuum cleaner, you'll need a range of materials. This includes microcontrollers like Arduino for controlling the robot's functions, sensors to detect obstacles and dirt, and a sturdy chassis to support the components.

The chassis is the framework on which the entire robot is built. It provides structural integrity and housing for the various electronic parts.

Arduino microcontrollers are essential for processing data from sensors and controlling the motors that drive the robot. Sensors, such as proximity sensors and dirt detection sensors, enable the robot to navigate spaces effectively and identify areas that require cleaning.

The chassis, often made of durable materials like plastic or metal, plays a vital role in protecting the internal components and ensuring the robot's stability during operation.

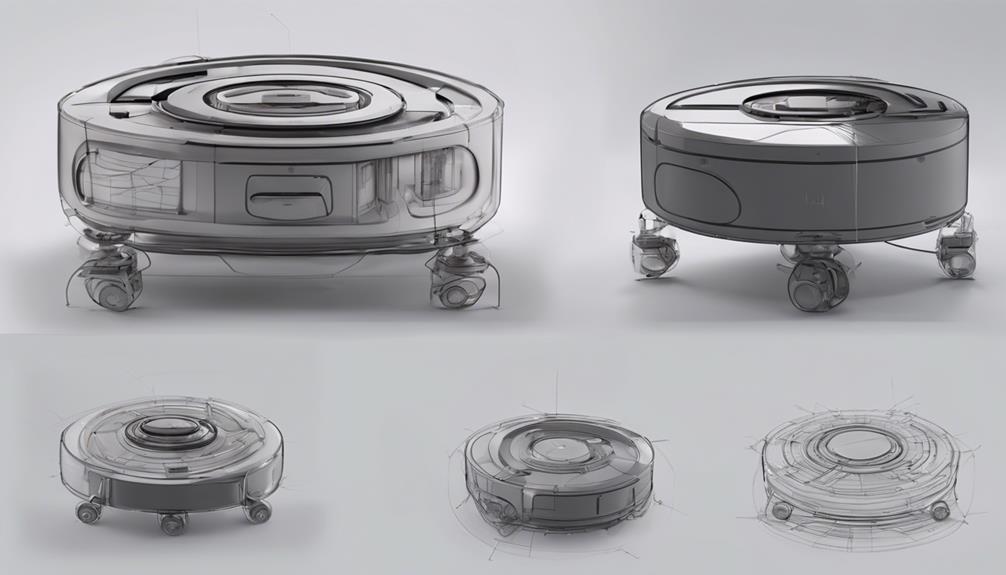

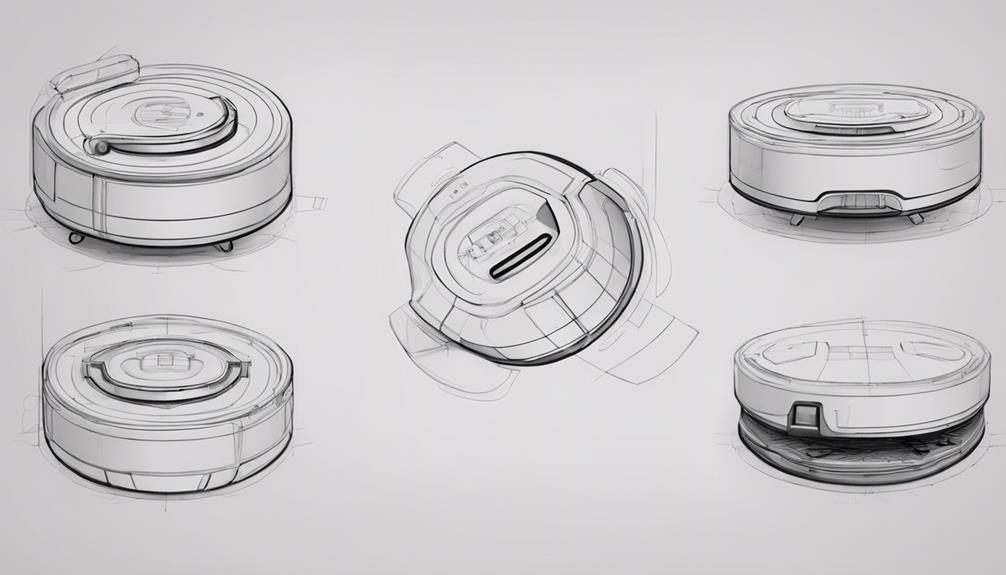

Designing the Robot Chassis

When designing the robot chassis, it's important to carefully select the material for durability and strength.

Consider adding support beams or braces to enhance the chassis structure and guarantee stability.

Additionally, custom wheel designs and proper motor placement are essential factors to optimize mobility and cleaning performance.

Chassis Material Selection

Consider selecting materials like acrylic, aluminum, or ABS plastic when designing the chassis for your robot vacuum cleaner to guarantee sturdiness and durability. These materials offer a balance between strength and weight, important for the chassis to support the components effectively. To help you make an informed decision, here is a comparison table showcasing the key features of each material:

| Material | Strength | Weight |

|---|---|---|

| Acrylic | High | Lightweight |

| Aluminum | Very High | Moderate |

| ABS Plastic | Moderate | Lightweight |

When designing the robot's chassis, it is vital to ensure it can withstand the weight of motors, wheels, ultrasonic sensors, and cleaning components. Additionally, incorporating support beams or braces can enhance the overall stability of the chassis. By choosing the right material and reinforcing the structure appropriately, you can create a robust chassis that will support the functionality of your robot vacuum cleaner effectively.

Wheel and Motor Placement

Selecting the appropriate placement for wheels and motors is key in optimizing the performance of your robot vacuum cleaner chassis. When designing the chassis layout, consider the following:

- Wheel Placement:

Place the wheels at the corners of the chassis to enhance stability and maneuverability. This configuration helps the robot navigate tight spaces and varying floor surfaces with ease.

- Motor Positioning:

Position the motors strategically to guarantee proper traction and efficient movement. By aligning the motors with the wheels and distributing weight evenly, you can enhance the overall performance of the robot vacuum cleaner.

- Chassis Layout:

Carefully plan the layout of the chassis to optimize the robot's ability to move around obstacles and clean efficiently. A well-thought-out chassis design contributes significantly to preventing slippage, enabling smooth navigation, and improving the cleaning capabilities of the robot.

Wiring and Circuit Setup

Wire the components of the robot vacuum cleaner, including motors, sensors, and motor drivers, according to the circuit diagram for optimal functionality.

Connect the Infrared (IR) sensors and ultrasonic sensors to the designated pins on the Arduino board to enable accurate detection and navigation.

Guarantee proper voltage regulation by incorporating the LM7805 voltage regulator in the circuit setup to maintain stable power supply.

Utilize the motor driver to control the movement of the vacuum cleaner motors efficiently.

Follow precise instructions for soldering components onto a perfboard, ensuring a reliable and effective circuit setup.

Attention to detail in the connections and placements of components is essential to prevent errors and ensure the smooth operation of the robot vacuum cleaner.

Sensor Placement and Functionality

When designing your robot vacuum cleaner, consider the essential positions for sensors and the type of sensor technology to use. Proper sensor placement and selection are vital for enabling your robot to navigate effectively and avoid obstacles while cleaning autonomously.

Strategic sensor deployment is key to ensuring efficient movement and cleaning operations for your robotic vacuum.

Optimal Sensor Positions

Strategically positioning sensors on a robot vacuum cleaner is essential for efficient obstacle detection and navigation.

- Front and Side Sensors: Ultrasonic sensors placed on the front and sides of the robot help detect obstacles in its path, enabling it to navigate around furniture and other objects during the cleaning process.

- Underside Infrared Sensors: Infrared sensors positioned underneath the robot serve to detect drop-offs like stairs or ledges, preventing the robot from falling and ensuring safe operation while cleaning.

- Comprehensive Coverage: Proper sensor placement is vital for efficient cleaning in diverse room layouts. By strategically locating sensors to cover different angles and distances, the robot can effectively navigate through rooms with varying obstacles, enhancing its overall cleaning performance.

Sensor Technology Selection

To guarantee peak performance, carefully consider the placement and functionality of sensors when selecting sensor technology for a robot vacuum cleaner. Sensors play a vital role in helping robots detect obstacles and navigate effectively during cleaning tasks.

Ultrasonic sensors are commonly utilized to detect objects in the robot's path, providing essential information for obstacle avoidance. Infrared sensors are also valuable as they can sense proximity to objects, further enhancing the robot's ability to maneuver around obstacles.

Proper placement of these sensors on the vacuum cleaner's chassis is essential to guarantee their effectiveness in detecting obstacles accurately.

These sensors are intricately connected to the robot's microcontroller, allowing for real-time feedback that aids in autonomous operations. By selecting the right sensor technology and placing them strategically on the robot vacuum cleaner, you can significantly enhance its obstacle detection capabilities, ultimately improving its overall cleaning performance.

Motor and H-Bridge Connection

Guarantee smooth control over your robot vacuum cleaner's movement by connecting the DC motors to the H-Bridge motor driver.

Here are some essential steps to confirm proper motor and H-Bridge connection for best functionality:

- Bidirectional Control: Utilize the H-Bridge to switch the direction of current flow to the motors, enabling forward, backward, and turning motions for your robot vacuum cleaner.

- Proper Wiring: Ensure a seamless operation by wiring the microcontroller, H-Bridge, and DC motors correctly. This step is important for the efficient coordination of components.

- Efficiency and Functionality: Properly configuring the connections between the DC motors and the H-Bridge is essential for the overall functionality and efficiency of your robot vacuum cleaner.

This setup allows for precise control over the robot's movements, enhancing its performance.

Ball Caster Mounting

Guarantee smooth movement and stability of your robot vacuum cleaner by properly installing the ball caster, an essential component for omnidirectional navigation. The ball caster mounting plays a pivotal role in confirming your robot vacuum cleaner can move effortlessly in various directions.

Typically positioned at the front or rear of the robot, the ball caster enables omnidirectional movement, allowing the robot to navigate around obstacles efficiently. By securing the ball caster correctly, you ensure that your robot vacuum cleaner can change directions effectively and maintain stability during operation.

With a variety of sizes and materials available for ball casters, you have the flexibility to customize based on your robot's specific design and requirements. Remember, the proper installation of the ball caster is essential for the efficient and consistent movement of your robot vacuum cleaner, enhancing its overall performance and usability.

Incorporating Bumper Design

Maximize obstacle detection and collision prevention by carefully integrating a well-designed bumper into your robot vacuum cleaner. When incorporating bumper design into your vacuum cleaner robot, consider the following:

- Sensors and Switches:

Equip the bumper with sensors or switches to detect contact with objects accurately. These components are vital for enabling the robot to sense obstacles and navigate around them effectively.

- Material Selection:

Choose suitable materials like rubber, foam, or plastic for the bumper construction. These materials can absorb impact, protecting both the robot vacuum cleaner and your furniture from damage during collisions.

- Calibration and Placement:

Ensure proper calibration and precise placement of the bumpers. Calibration is important to adjust the sensitivity of the bumpers for accurate obstacle detection, while strategic placement enhances the robot's ability to navigate obstacles efficiently.

Programming and Testing

Consider writing code using Arduino IDE to program the cleaning robot for autonomous movement. Utilize the Arduino platform to control the motors of the robot by sending signals through digital pins. This allows you to precisely manage the movement of the cleaning robot, enabling it to navigate spaces effectively.

Test the robot's movements and sensor readings to confirm it can accurately detect obstacles and navigate around them. Make necessary adjustments to the code and hardware to optimize the robot's performance, guaranteeing it functions well in cleaning and obstacle avoidance tasks.

Conduct thorough testing to verify the efficiency and effectiveness of the cleaning robot, making sure it operates smoothly and reliably. By programming and testing the robot meticulously, you can fine-tune its capabilities and enhance its overall functionality for top-notch cleaning performance.

Enhancements and Maintenance

To keep your cleaning robot performing at its best, regular maintenance and strategic enhancements are essential for peak functionality and efficiency. Here are some key ways to enhance and maintain your floor cleaning robot:

- Regular Maintenance:

- Empty the dustbin.

- Clean the brushes.

- Check for any clogs or obstructions to guarantee optimal performance.

- Enhancements:

- Consider adding additional sensors for improved navigation.

- Upgrade cleaning components for better performance.

- Integrate smart home features for added convenience.

- Battery and Algorithm Optimization:

- Upgrading the battery capacity can extend operating time.

- Optimizing motor control algorithms can improve efficiency and battery life, ensuring your robot can clean effectively for longer periods.

Frequently Asked Questions

How to Make a Robotic Vacuum Cleaner?

To make a robotic vacuum cleaner, you need to choose a microcontroller for its brain, assemble a sturdy chassis, select motors and sensors, wire everything up, and program it for cleaning tasks. Test it thoroughly and troubleshoot any issues for best performance.

How to Make a Vacuum Cleaner Step by Step?

You want to make a vacuum cleaner step by step? First, gather your tools like a conductor orchestrating a symphony. Then, assemble the pieces like a puzzle master. Finally, program and test your creation like a scientist revealing a breakthrough.

What Are the Parts of a Robot Vacuum?

To design a robot vacuum, consider components like motors, wheels, sensors, and a cleaning mechanism. Sensors aid navigation and dirt detection, while motors power movement and cleaning. These parts collaborate to create an efficient autonomous floor-cleaning robot.

How Are Robot Vacuums Programmed?

When it comes to programming robot vacuums, algorithms dictate their every move. Sensors like infrared or ultrasonic help them detect obstacles, while mapping algorithms guarantee thorough cleaning. Did you know they can even return to their charging station automatically?

Can I Use the DIY Guide to Make Modifications to My Existing Robot Vacuum Cleaner?

Yes, you can use the DIY guide to make modifications to your existing simple robot vacuum cleaner. By following the step-by-step instructions, you can enhance its performance and add new features according to your specific needs and preferences. The guide makes it convenient to customize your robot vacuum to suit your requirements.

Conclusion

To sum up, designing a robot vacuum cleaner requires careful planning and execution. Just like a well-oiled machine, each component must work in harmony to achieve peak performance.

By following the step-by-step guide provided, you can create a robotic cleaner that efficiently navigates your home. Remember, attention to detail and precision are key to success in this project.

Happy designing!