To start developing a robot vacuum cleaner, begin by exploring biomimicry for ideas drawn from animals like ants and geckos. Determine its functions: sweeping, suction, obstacle detection. Acquire materials such as microcontrollers, motors, and sensors, taking into account their weight and durability. Design sketches and incorporate nature-inspired elements for enhanced efficiency. Use 3D printing to create customized components, carefully install sensors and motors, then program and test using Arduino IDE for optimal performance. Stay tuned to learn the detailed process from concept to realization of your robot vacuum cleaner! Once the design and programming are finalized, conduct thorough testing to ensure the robot vacuum cleaner operates smoothly and efficiently. Adjust its functions and fine-tune as needed to enhance its performance. When the robot vacuum cleaner is fully operational, it can be manufactured on a large scale and introduced to the market for consumers to enjoy the benefits of automated cleaning.

Key Takeaways

- Research biomimicry for design inspiration from nature.

- Gather materials and components for efficient cleaning functions.

- Design robot for optimal performance and maneuverability.

- Implement sensors and motors accurately for autonomous operation.

- Program and test the robot thoroughly for peak efficiency.

Researching Biomimicry for Inspiration

When researching biomimicry for inspiration, you can find innovative solutions by studying nature's designs and processes. One fascinating example of biomimicry in the field of robotics is the development of vacuum robots. Drawing inspiration from nature, engineers have looked at how animals efficiently navigate and clean their environments to enhance the capabilities of these automated devices.

By observing the way animals like ants or bees organize their tasks collectively, vacuum robots have been programmed to work collaboratively to cover a large area efficiently.

Additionally, studying the locomotion of animals like geckos or cockroaches has led to the development of robots that can climb walls and navigate various surfaces effortlessly.

Furthermore, the concept of self-repair in plants has inspired the creation of vacuum robots that can detect and repair minor malfunctions autonomously.

These biomimetic approaches not only improve the performance of vacuum robots but also contribute to the advancement of robotics technology as a whole.

Defining Robot Actions and Functions

When defining the actions and functions of your robot vacuum cleaner, consider task execution planning, motion and navigation, and sensor integration.

These key points will help outline how your robot will move, clean, and sense its surroundings efficiently.

Task Execution Planning

To effectively define the actions and functions of a robot vacuum cleaner, consider specifying cleaning tasks like sweeping and suction, along with implementing features such as obstacle detection and room mapping.

When planning the task execution for the robot, it's important to incorporate components like the Motor Driver to control the movement and operation of the vacuum cleaner. By determining the sequence of actions, including start-up procedures, the cleaning cycle, and the docking process for recharging, you guarantee efficient and effective performance.

Integration of side brushes, collision sensors, and return-to-base capabilities enhances the robot's functionality in moving and cleaning various spaces. Additionally, the inclusion of automatic charging ensures the robot is always ready to tackle cleaning tasks.

Aligning the robot's actions and functions with the overall cleaning objectives and user requirements is essential for creating a robot vacuum cleaner that provides thorough and convenient cleaning solutions.

Motion and Navigation

Define specific actions for the robot, such as cleaning, moving, turning, and avoiding obstacles, when focusing on Motion and Navigation in creating a robot vacuum cleaner. To guarantee efficient movement and navigation, the integration of infrared sensors is essential. These sensors help the robot detect obstacles in its path, allowing it to adjust its course and avoid collisions. By implementing navigation functions like obstacle detection using infrared sensors, the robot can autonomously maneuver through different areas for effective cleaning.

To further elaborate on the importance of infrared sensors in motion and navigation, let's look at the following table:

| Infrared Sensors in Motion and Navigation | Description |

|---|---|

| Obstacle Detection | Detects obstacles for collision avoidance. |

| Path Planning | Assists in defining the most suitable cleaning paths. |

| Navigation Assistance | Guides the robot in moving efficiently. |

| Area Coverage | Ensures thorough cleaning coverage. |

| Return-to-Base Functionality | Enables the robot to find its docking station. |

Sensor Integration

Incorporating sensors into a robot vacuum cleaner is essential for defining its actions and functions efficiently. These sensors, including ultrasonic and infrared sensors, play a vital role in enhancing the robot's navigation and cleaning capabilities.

Ultrasonic sensors can detect obstacles up to 25 meters away, aiding in smooth navigation and obstacle avoidance. On the other hand, infrared sensors are proficient at identifying thick garbage and obstacles within a range of 25 cm, ensuring thorough cleaning.

Additionally, dust sensors are pivotal in activating cleaning processes when dust levels reach or exceed 0.30 mg/mm3, maintaining excellent cleaning efficiency.

The integrated circuit of sensors within the robot vacuum cleaner harmonizes their functions, providing thorough obstacle detection and cleaning efficiency. By working together seamlessly, these sensors allow the robot vacuum cleaner to navigate efficiently, avoid obstacles, and clean effectively, ensuring a complete cleaning experience for your home.

Gathering Design Materials

When gathering design materials for your robot vacuum cleaner, it's important to carefully select components like microcontrollers, motors, chassis, and sensors. Consider factors such as weight, size, and durability to guarantee the functionality and longevity of your robot.

Additionally, exploring prototype building techniques using craft materials like aluminum foil, clay, and paper cups can aid in hands-on design exploration.

Material Selection Process

Consider evaluating various materials like aluminum foil and craft sticks for the robot's structure based on their durability and weight. Aluminum foil can provide a lightweight yet sturdy frame, while craft sticks offer a balance between strength and flexibility.

For detailed components, materials like clay and pipe cleaners can be assessed for their flexibility and ease of manipulation. When it comes to quick prototyping and testing phases, disposable materials such as paper cups and plates can be a practical choice.

To sketch out design ideas and visualize features of the robot vacuum cleaner, drawing materials like pencils and markers are essential. During the design process, securing components together with masking tape allows for easy adjustments and modifications.

Prototype Building Techniques

To begin the process of prototype building for your robot vacuum cleaner, gather a variety of materials such as aluminum foil, craft sticks, clay, string, disposable items like paper cups, plates, and toothpicks, along with masking tape and drawing materials like pencils and markers. These materials will be instrumental in creating a functional prototype that can mimic the essential functions of a vacuum cleaner. Below is a table outlining the key materials you will need for your prototype building:

| Materials | Purpose | Usage |

|---|---|---|

| Aluminum foil | Flexible component | Create flexible parts such as sensor holders |

| Craft sticks | Structural support | Build the framework and structure of the prototype |

| Clay | Malleable material for shaping | Mold intricate parts like the vacuum cleaner's nozzle |

| String | Mechanical connections | Test mechanisms such as brush rotation |

| Disposable items | Temporary components for testing | Prototype components like wheels and sensors |

Experimenting with these materials will help you refine your vacuum cleaner prototype's design and functionality.

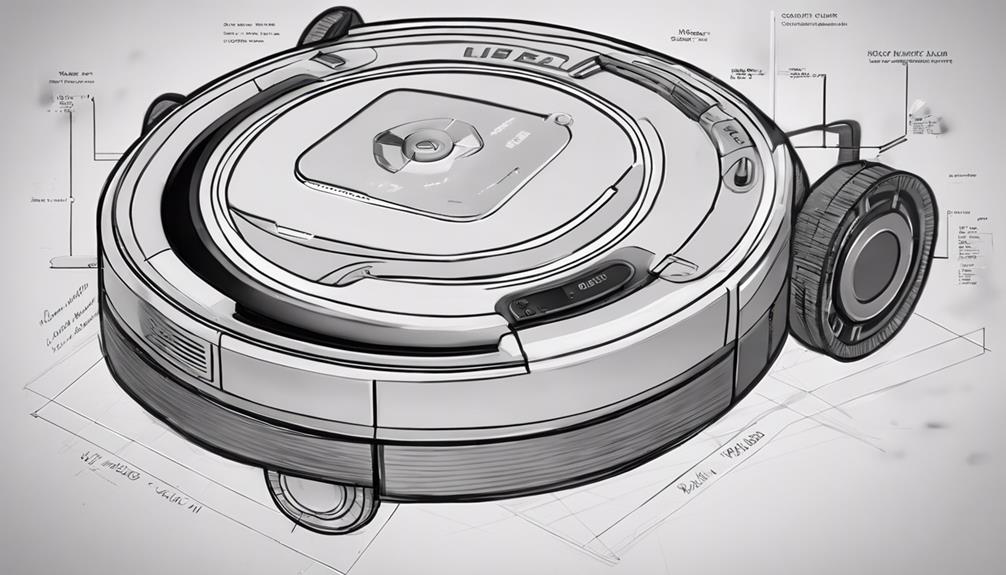

Sketching Out Robot Design

Visualizing the overall appearance and structure of the robot vacuum cleaner is vital when sketching out its design. Detailed sketches play a significant role in determining the size, shape, and placement of key components such as motors, sensors, and cleaning mechanisms.

When sketching the design of the robot, it's essential to take into account factors like weight distribution, maneuverability, and accessibility to guarantee top performance.

Sketching out the robot design allows for multiple iterations and modifications before moving on to the detailed design phase. Clear and annotated sketches serve as a blueprint for the actual construction of the robot vacuum cleaner.

Incorporating Nature-Inspired Features

When designing a robot vacuum cleaner, incorporating nature-inspired features can enhance its cleaning capabilities and efficiency. By drawing inspiration from natural processes and creatures, such as the sorting and grabbing actions of animals like the platypus and octopus, innovative functionalities can be developed.

Biomimicry in robot design not only leads to more effective cleaning but also fosters sustainability and eco-friendliness. Through the integration of nature-inspired elements, robot vacuum cleaners can achieve a unique set of features that set them apart in performance and functionality.

Researching how animals perform tasks can guide the development of robots with enhanced capabilities, making them more efficient in their cleaning tasks. Ultimately, incorporating nature-inspired features in robot vacuum cleaners aligns with the goal of creating sustainable and environmentally friendly cleaning solutions, paving the way for innovative advancements in the field of robotics.

Implementing 3D Printing Technology

Implementing 3D printing technology revolutionizes the production process of robot vacuum cleaners by enabling the creation of custom-designed components. This cutting-edge technology allows for the fabrication of intricate parts such as the chassis, housing, and specialized components with high precision and efficiency. Not only does 3D printing streamline the manufacturing process, but it also offers the flexibility to modify designs easily, leading to optimized performance of the robot vacuum cleaner. By utilizing 3D printing, manufacturers can rapidly prototype and test various configurations, ensuring that the final product meets the desired specifications. This innovative approach reduces production time and costs while maintaining the accuracy and quality of the components.

| Advantages of 3D Printing Technology |

|---|

| Custom-designed components |

| Rapid prototyping and testing |

| Cost-effective production process |

When integrating 3D printing technology, it also allows for the creation of intricate parts like the microcontroller housing, ensuring a snug fit and excellent functionality for the robot vacuum cleaner.

Installing Sensors and Motors

To guarantee peak performance, the robot vacuum cleaner requires accurate installation of sensors and motors. Sensors such as ultrasonic and infrared play an essential role in detecting obstacles and dust along the robot's movement path. Proper calibration and placement of these sensors ensure effective obstacle detection and efficient cleaning.

On the other hand, motors are indispensable for driving the robot's movement, enabling it to navigate and clean various surfaces effectively. Precise connection of motors to the microcontroller is necessary to control the speed and direction of the robot accurately.

The integration of sensors and motors is crucial for the autonomous operation and functionality of the robot vacuum cleaner. By ensuring the proper installation and synchronization of these components, the robot can move seamlessly, detect obstacles, and clean efficiently, providing a thorough cleaning experience for users.

Programming and Testing the Robot

Begin by writing code using Arduino IDE to program the robot's movements and sensor interactions. By coding the robot to move forward, you can test its basic functionality. Run the programmed code and observe how the robot responds to commands.

Make sure that the sensors are detecting obstacles accurately and that the motors are propelling the robot in the intended direction. Make any necessary adjustments to the code to improve the robot's performance and accuracy.

During testing, check that all sensors, motors, and components are functioning correctly. Conduct thorough tests to verify that the robot operates as intended before using it for cleaning tasks.

By meticulously testing the robot's movements and sensor interactions, you can fine-tune its programming to ensure peak performance. Remember to document any changes made to the code for future reference.

Testing is an essential step in the development process to guarantee that the robot vacuum cleaner functions effectively and efficiently.

Frequently Asked Questions

How to Make a Robotic Vacuum Cleaner?

To make a robotic vacuum cleaner, start by designing a DIY robot with Arduino Uno, motors, and sensors. Assemble the chassis using Solidworks and 3D print. Implement cleaning algorithms, connect components, program the microcontroller, and test for efficiency.

What Is the Concept of Robotic Vacuum Cleaner?

To understand the concept of a robotic vacuum cleaner, think of it like this: it's a smart device that navigates and cleans floors on its own. Sensors help it avoid obstacles and map out efficient cleaning paths.

How to Make a Vacuum Cleaner Step by Step?

To make a vacuum cleaner step by step, start by designing a chassis, assembling components like Arduino Uno and sensors, and following wiring and programming instructions for autonomy. Upgrade with encoders and navigation algorithms for better performance.

What Was the First Prototype of a Robotic Vacuum Cleaner?

Imagine stepping into the past, where 'Genghis' emerged as the pioneer of robotic vacuum cleaners. Its basic design, relying on infrared sensors, marked the dawn of a new era in automated cleaning technology.

What Are the Key Steps in Creating a Robot Vacuum Cleaner from Concept to Creation?

When creating a robot vacuum cleaner, it’s important to follow stepbystep robot vacuum instructions. First, researchers develop a concept, then engineers design the mechanics. Next, programmers write the software, manufacturers assemble the parts, and quality control ensures the final product is effective.

Conclusion

To sum up, developing a robot vacuum cleaner entails a meticulous process of research, design, and testing. Once the robot vacuum has been designed and tested, the next step is setting up your robot vacuum in the desired space. This involves programming the cleaning schedule, ensuring the vacuum is connected to the charging dock, and mapping out the cleaning area. Overall, developing a robot vacuum cleaner is a complex and intricate process that requires attention to detail at every stage.

Did you know that the global market for robotic vacuum cleaners is projected to reach $3.5 billion by 2025?

By incorporating nature-inspired features, utilizing advanced technology, and thorough programming, you can create a cutting-edge robot vacuum cleaner that meets the demands of modern households.

Keep innovating and exploring new possibilities in the exciting world of robotics!