To create a small robot vacuum cleaner, you will require a microcontroller, motors, chassis, wheels, power supply, and sensors for navigation. Keep the design compact (196mm x 196mm), 3D print the necessary parts, and utilize a radial blower vacuum motor. Incorporate sensors such as infrared and ultrasonic for obstacle detection. Use an H-Bridge module to connect motors for precise movement. Attach a ball caster for stability and maneuverability. Strategically integrate sensors, program them for navigation and obstacle avoidance, and ensure proper sensor calibration for efficient cleaning. For more detailed instructions on constructing your DIY robot vacuum, delve further into the functionality and setup details.

Key Takeaways

- Design compact chassis (196mm x 196mm) for easy maneuverability and space efficiency.

- Integrate sensor-based navigation with infrared and ultrasonic sensors for obstacle detection.

- Connect motors with H-Bridge module for efficient movement control and direction management.

- Mount ball caster securely for stable and smooth navigation on different surfaces.

- Program sensors for autonomous cleaning, calibration, and obstacle avoidance in the DIY robot vacuum cleaner.

Top picks for "make small robot"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

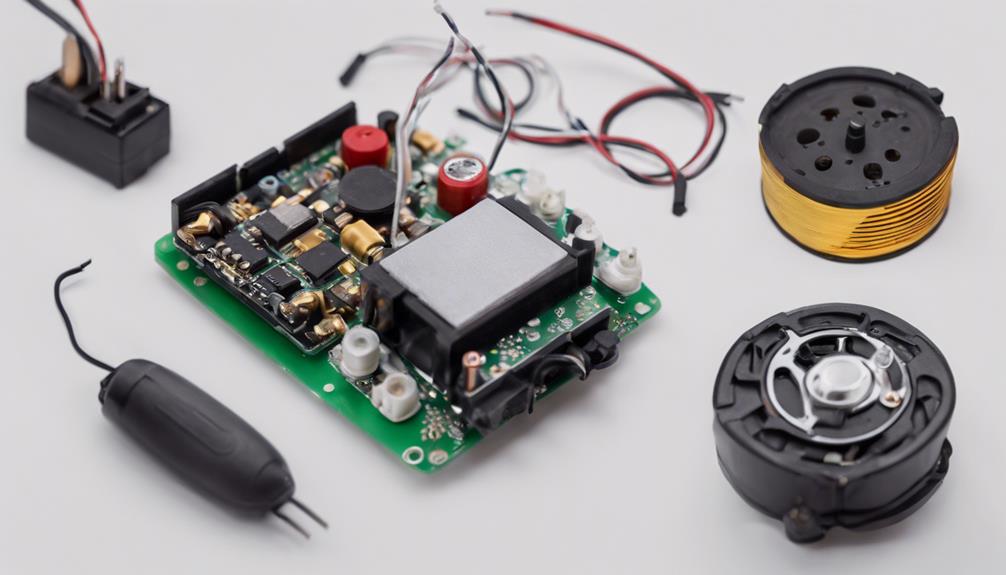

Materials Needed

To build your own DIY small robot vacuum cleaner, gather essential materials such as a microcontroller, motors, chassis, wheels or tracks, and a power supply. With these materials, you can then assemble the components to create a simple robot vacuum cleaner. The microcontroller will serve as the brain of the robot, controlling its movements and vacuum functions. The motors will provide the necessary power to move the robot around, while the chassis, wheels or tracks, and power supply will give it the physical structure and energy needed to operate.

The chassis serves as the foundation of your robot vacuum, providing structural support and housing for the electronic components. You can construct the chassis using materials like cardboard or acrylic, ensuring a balance between lightweight design and durability.

Motors play an important role in powering the movement of the robot, allowing it to navigate and clean efficiently. Wheels or tracks attached to the motors enable the robot to move smoothly across different surfaces, enhancing its mobility and cleaning capabilities.

Additionally, sensors such as ultrasound or IR sensors are necessary for enabling navigation and obstacle avoidance, connecting to the microcontroller to provide essential input for controlling the robot's movements.

Understanding the Functionality

Understanding how a small robot vacuum cleaner functions involves motorized movement, suction power for dirt collection, and sensor-based navigation.

Here are some key points to keep in mind:

- Motorized Movement: The motors in the body of the robot create the necessary movement to propel it across the floor, ensuring efficient cleaning in different areas of a room.

- Suction Power: The cleaning robot's suction power, generated by the vacuum motor, effectively collects dirt and debris from various surfaces, such as carpets or hardwood floors.

- Sensor-Based Navigation: Sensors like infrared or ultrasonic play an important role in detecting obstacles, enabling the robot to navigate around furniture and other objects during its cleaning operation.

- LiPo Battery: The LiPo battery powers the entire system, providing the necessary energy for the motors, vacuum, sensors, and microcontrollers to function harmoniously, allowing the robot vacuum cleaner to perform its cleaning tasks autonomously.

Understanding the intricate interplay of these components is essential for the successful functionality of your DIY robot vacuum cleaner.

Design Specifications

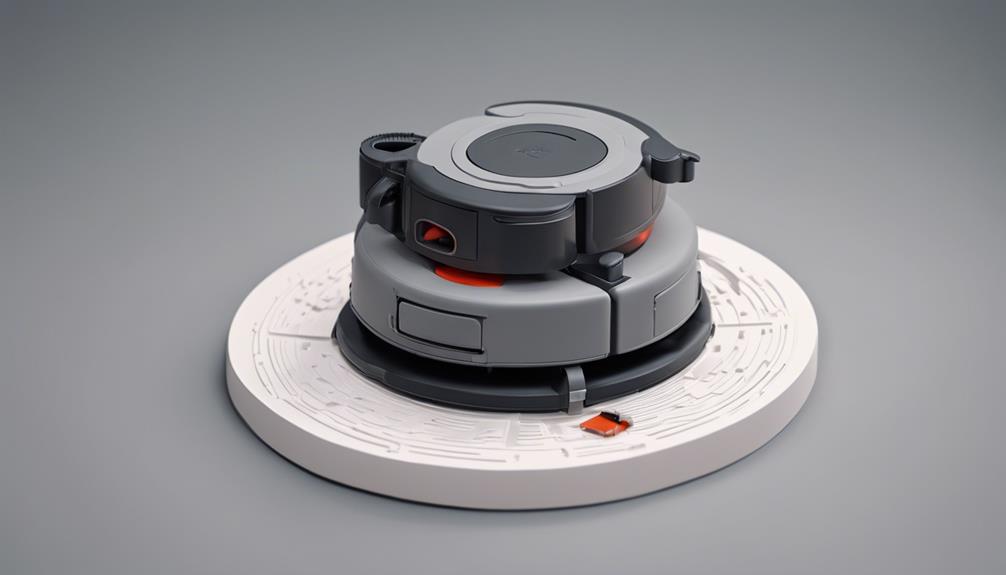

Exploring the design specifications of a small robot vacuum cleaner reveals key features that contribute to its efficient performance and functionality. The compact footprint of 196mm x 196mm guarantees that the robot can maneuver easily in tight spaces, ensuring everything is thoroughly cleaned.

Being 3D-printable allows for customization and easy assembly, giving you the flexibility to tailor the robot to your specific needs. The inclusion of a radial blower vacuum motor ensures powerful suction for effective cleaning, making sure every little bit of dirt is picked up.

Additionally, the integration of ultrasonic sensors enables obstacle detection, facilitating autonomous movement around obstacles in the cleaning path. To maintain air quality, a HEPA air filter is incorporated to make sure that cleaner exhaust air is expelled back into the environment.

These design specifications work together harmoniously to create a small robot vacuum cleaner that's both efficient and effective in keeping your space clean.

3D Printing Process

Delving into the 3D printing process for creating the small robot vacuum cleaner involves translating the digital model of its chassis into physical components. Here's a concise guide to help you understand the process:

- Digital Model Creation:

Begin by designing the vacuum robot's chassis using software like Solidworks, ensuring precise measurements and structural integrity.

- Layer Slicing and G-Code Conversion:

The digital model is segmented into layers and converted into G-code instructions for the 3D printer to produce each layer accurately.

- PLA Filament Usage:

Opt for PLA filament when 3D printing the chassis due to its printability and robustness, ensuring a sturdy final product.

- Customization and Precision:

The 3D printing process offers the flexibility to customize and refine the robot's design, allowing for intricate and tailored components that perfectly fit the vacuum cleaner.

Sensor Installation

To enhance your DIY small robot vacuum cleaner, you should carefully select sensor types that best suit your navigation needs. Strategically place these sensors on the chassis to guarantee effective obstacle detection and avoidance.

It's crucial to calibrate the sensor sensitivity for accurate data processing and reliable operation.

Sensor Types Selection

How can you guarantee the best sensor installation for your DIY small robot vacuum cleaner to enhance obstacle detection and navigation capabilities?

Selecting the right sensor types is essential for the efficient operation of your small robot vacuum cleaner. Here are some key considerations:

- Infrared Sensors:

These sensors are ideal for detecting obstacles in the path of the robot vacuum cleaner, allowing it to navigate around furniture and other objects with ease.

- Ultrasonic Sensors:

Utilize ultrasonic sensors for accurate distance measurement, especially in tight spaces where precision navigation is vital for effective cleaning.

- Contact Sensors:

Implement contact sensors to detect collisions with walls or furniture during the cleaning process, preventing damage to both the robot vacuum cleaner and your belongings.

- Calibration and Testing:

Properly calibrate and test your sensors to ensure accurate obstacle detection and reliable navigation capabilities, enhancing the overall performance of your DIY small robot vacuum cleaner.

Placement for Effectiveness

Strategically position the infrared sensors around your DIY small robot vacuum cleaner to guarantee effective obstacle detection. Place the sensors at varying heights to make sure they can detect obstacles of different sizes.

It's vital to install the sensors in locations where they've a clear line of sight to prevent false readings. By positioning the sensors in a manner that covers all angles around the robot, you can achieve thorough obstacle detection capabilities.

Testing the sensor placements is important to fine-tune the robot's navigation and optimize its performance. Make sure to experiment with different sensor configurations to find the most efficient setup for your specific robot design.

Calibrating Sensor Sensitivity

You can enhance the obstacle detection accuracy of your DIY small robot vacuum cleaner by adjusting the sensor sensitivity through modifying the threshold values in the code.

To calibrate the sensor sensitivity effectively, follow these steps:

- Trial and Error Approach: Experiment with different threshold values in the code to find the best sensitivity level for obstacle detection.

- Testing with Various Obstacles: Test the sensors with different types of obstacles to guarantee accurate detection across various scenarios.

- Fine-Tuning Sensor Placement: Adjust the sensor positions to maximize coverage and reduce false positives in obstacle detection.

- Calibrating Distance Range: Calibrate the sensor's distance range settings to accurately detect obstacles at varying distances, ensuring thorough coverage during operation.

Motor and H-Bridge Connection

To control the speed and direction of the DC motor in your DIY small robot vacuum cleaner, connect it to the H-Bridge module using jumper wires. The H-Bridge allows you to manage the movement of the motor efficiently.

Make sure you connect the motor terminals to the H-Bridge with the correct polarity alignment to prevent any issues with the motor's operation. By utilizing the control signals from the microcontroller, you can command the motor to move forward, backward, or stop as needed for the robot vacuum cleaner's functionality.

Before integrating the motor and H-Bridge into your project, it's important to test the connection to confirm that everything is working correctly.

Ball Caster Mounting

Mount the ball caster securely at the front of your robot vacuum to guarantee stability and smooth navigation.

Here are some key points to bear in mind for effective ball caster mounting:

- Secure Attachment: Make sure the ball caster mount is firmly fixed to the chassis of the robot vacuum to prevent any wobbling or instability during operation.

- Proper Alignment: Position the ball caster correctly to allow for best movement around obstacles and easy direction changes.

- Quality Components: Select a high-quality ball caster and mount to enhance durability and longevity of your robot vacuum cleaner.

- Consider Maneuverability: The alignment and positioning of the ball caster play a critical role in the overall maneuverability of the robot, impacting its ability to navigate smoothly.

Sensor Integration and Programming

To tackle the Sensor Integration and Programming aspect of your DIY small robot vacuum cleaner, you'll need to focus on three key points:

Sensor Setup Basics

Programming Essentials

Integration Techniques

These elements are vital in ensuring your robot can effectively navigate and clean your space.

Sensor Setup Basics

For accurate navigation and obstacle avoidance in your DIY small robot vacuum cleaner, integrating sensors with the microcontroller is a crucial step. Sensors like ultrasonic or infrared play an essential role in detecting obstacles.

Follow these sensor setup basics to guarantee your robot functions effectively:

- Proper Integration: Make sure sensors are connected correctly to the microcontroller for seamless communication.

- Strategic Placement: Position sensors strategically on the robot's chassis to cover all angles for thorough obstacle detection.

- Programming: Program the sensors to interpret data accurately and make real-time decisions for navigation and obstacle avoidance.

- Testing and Calibration: Regularly test and calibrate the sensors to maintain peak performance and reliability of your cleaning robot.

Programming Essentials

Make sure you have successfully integrated sensors like ultrasonic or infrared to effectively program inputs for controlling your small robot vacuum cleaner using the Arduino IDE. By incorporating these sensors, you enable obstacle detection and navigation capabilities, important for the efficient operation of your robot. Utilize the Arduino IDE to create code that interprets sensor data and adjusts the robot's movements accordingly. Implementing logic in your programming is essential to guarantee that the robot responds appropriately to the information gathered by the sensors. Proper calibration and placement of sensors on the robot chassis are essential for accurate readings that drive the robot's behavior. Test the functionality of the sensors in various environments to fine-tune the responsiveness of your robot vacuum cleaner.

| Sensor Type | Purpose | Integration Tips |

|---|---|---|

| Ultrasonic | Obstacle Detection | Ensure consistent power supply. |

| Infrared | Navigation and Object Detection | Check for interference from other sources. |

| Light Sensor | Ambient Light Detection | Adjust sensitivity levels for best performance. |

| Touch Sensor | Bumper Detection | Securely attach to prevent false triggers. |

| Gyroscope | Orientation and Movement | Calibrate for accurate readings. |

Integration Techniques

Integrating sensors into your small robot vacuum cleaner enables precise obstacle detection and navigation capabilities essential for its efficient operation. By incorporating ultrasonic or IR sensors, you can enhance the cleaning robot's ability to detect obstacles and navigate around them effectively.

Here are some key integration techniques to optimize your robot vacuum cleaner:

- Utilize Arduino Programming: Employ Arduino programming to process sensor data and enable autonomous movement control for your robot.

- Implement Calibration: Calibrate sensor readings to guarantee accurate obstacle detection and avoidance during the cleaning routine.

- Combine Sensor Data with Motor Control Algorithms: Enhance the robot's responsiveness to its environment by integrating sensor data with motor control algorithms.

- Ensure Smooth Operation: Implement sensor integration techniques meticulously to uphold smooth operation and maximize cleaning performance.

Frequently Asked Questions

How to Make a Small Robot Vacuum Cleaner?

To make a small robot vacuum cleaner, start by choosing a microcontroller like Arduino. Assemble a sturdy chassis with materials like cardboard. Attach motors and wheels for movement. Add sensors for navigation. Equip with a vacuum for cleaning.

How to Make a Simple Robot at Home With Household Items?

You can make a simple robot at home with household items. Use a DC motor, cardboard, wheels, and a power source to create a robot base. Attach a vacuum cleaner or brush, program it with a microcontroller, test, and adjust as needed.

How Do You Make a Simple Vacuum?

To make a simple vacuum, design a chassis and select components like motors, sensors, and a microcontroller. Assemble the robot by 3D printing the chassis, connecting components, and ensuring proper wiring for motor control and sensor input.

How to Make Mini Bots?

To make mini bots, start by integrating Arduino microcontrollers and small motors. Add sensors like ultrasonic and IR for obstacle detection. Mini bots are great for educational projects and hobbyists, offering hands-on experience in robotics.

Are the DIY Tips for Making a Small Robot Vacuum Cleaner applicable to making a more advanced Robot Vacuum Cleaner for Tech Enthusiasts?

Yes, the DIY tips for making a small robot vacuum can definitely be utilized in creating a more advanced robot vacuum cleaner for tech enthusiasts. By following the steps and using the right components, you can make your own robot vacuum that meets higher standards and caters to advanced technology enthusiasts.

Conclusion

To sum up, creating your own small robot vacuum cleaner is a rewarding DIY project that can be both fun and educational.

By following the steps outlined in this guide, you can build a functional and efficient robot that helps with your cleaning tasks.

With a little creativity and technical know-how, you can bring your robotic creation to life and watch it navigate your home with ease, like a tiny, automated cleaning companion.