To effectively monitor filter pressure and backwashing thresholds, you should use reliable pressure gauges or digital sensors to track system performance regularly. Set thresholds based on your system type and manufacturer guidance to trigger backwashes before clogs cause flow issues or damage. Keep an eye on pressure trends and maintain logs to anticipate maintenance needs. Managing these parameters proactively helps you avoid costly repairs and extends equipment life—discover more insights to optimize your filtration system.

Key Takeaways

- Regularly monitor pressure gauges or sensors to detect fluctuations indicating filter clogging or leaks.

- Set backwash thresholds based on system specifications to optimize cleaning frequency and prevent over- or under-washing.

- Use automated alerts to receive real-time notifications when pressure differences exceed safe limits.

- Log pressure data and backwash events to identify trends and plan proactive maintenance schedules.

- Maintain proper thresholds to ensure efficient filtration, extend filter media lifespan, and reduce operational costs.

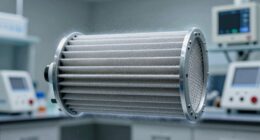

Monitoring filter pressure and backwashing thresholds is essential for maintaining ideal filtration system performance. When you keep an eye on pressure readings, you can quickly identify pressure fluctuations that indicate potential problems. These fluctuations often signal that the filter media is becoming clogged or that there’s an issue with flow rates. If you notice a steady increase in pressure over time, it’s a clear sign that the filter is trapping more debris and needs attention. Conversely, sudden drops in pressure might suggest leaks or filter damage. Regularly checking pressure values helps you stay ahead of these issues, preventing costly damage and ensuring the system operates efficiently.

Understanding backwash triggers is crucial for optimizing your filtration process. Backwashing is the process of cleaning the filter media by reversing flow or using air to remove accumulated debris. You want to establish specific pressure thresholds that serve as triggers for backwashing. Typically, when the pressure difference between the inlet and outlet exceeds a predetermined level, it’s time to backwash. This threshold varies depending on your system and media type, but it’s vital to adhere to manufacturer recommendations or your operational standards. If you wait too long to backwash, the filter may become overly clogged, reducing flow rates and increasing energy consumption. On the other hand, backwashing too frequently can waste water and disrupt operations unnecessarily. By setting clear backwash triggers based on pressure readings, you ensure the process is both effective and economical.

To effectively monitor these parameters, you should install reliable pressure gauges at strategic points in your system. Digital sensors can provide real-time data, allowing you to respond promptly to pressure fluctuations. Many modern systems also offer automated alerts when pressure reaches backwash thresholds, simplifying maintenance. Regular visual inspections of gauges help confirm readings and catch any anomalies early. Keep a detailed log of pressure trends and backwash events; this data helps you refine your thresholds over time, making your maintenance more predictive than reactive. Additionally, understanding dog breed characteristics can help tailor maintenance schedules for specific filter media types. This proactive approach minimizes downtime, extends filter media lifespan, and conserves resources.

Frequently Asked Questions

How Often Should Filter Pressure Be Checked Daily?

You should check the filter pressure at least twice daily to guarantee ideal operation. During these checks, verify the pressure gauge calibration to detect any inaccuracies. Regularly monitoring pressure helps identify when backwashing is needed, fitting into your filter maintenance schedule. By staying proactive, you prevent system issues, extend equipment life, and maintain water quality. Consistent checks are essential for effective filter management and ensuring your system runs smoothly.

What Are the Signs of Ineffective Backwashing?

Ever wonder if your backwashing is effective? Signs of ineffective backwashing include persistent filter clogging, cloudy or dirty water, and increased pressure readings that don’t decrease after backwashing. You should also check if the pressure gauge is properly calibrated, as inaccurate readings can hide underlying issues. If pressure remains high or water quality doesn’t improve, it’s time to reevaluate your backwashing process to guarantee proper filter maintenance.

Can Automatic Backwashing Damage the Filter Media?

Automatic backwashing generally doesn’t damage your filter media if set correctly, but excessive backwash frequency can cause filter media degradation over time. If you backwash too often, you risk stripping away fine particles, reducing filter effectiveness. To prevent damage, confirm your system’s backwash cycle is well-calibrated, and monitor the filter’s performance regularly. Proper maintenance helps extend the life of your filter media and keeps your system running smoothly.

How Does Temperature Affect Filter Pressure Readings?

Temperature fluctuations can substantially affect your filter pressure readings by causing the pressure sensor to drift, leading to inaccurate measurements. Warmer temperatures may reduce water viscosity, lowering pressure readings, while colder temps can increase them. To guarantee accuracy, you should regularly check and calibrate your pressure sensors, especially during temperature changes. Proper calibration helps maintain reliable pressure data, ensuring you backwash at the right thresholds and avoid unnecessary filter media damage.

Are There Alternative Methods to Monitor Filter Performance?

Yes, you can use alternative methods like sensor calibration and chemical compatibility checks to monitor filter performance. Regularly calibrate sensors to guarantee accurate readings, and verify that materials are compatible with your system’s chemicals to prevent corrosion or damage. These methods help you detect issues early, optimize filter operation, and extend equipment lifespan, all while maintaining reliable performance without solely relying on pressure measurements.

Conclusion

Keep a close eye on your filter pressure and backwashing thresholds like a vigilant captain steering through choppy waters. When you catch the signs early, you prevent the storm from sinking your system. Regular monitoring is your lighthouse, guiding you safely past potential blockages and overflows. With steady attention, your filtration system will run smoothly, like a well-oiled engine, ensuring clear, clean water flows effortlessly—making your water treatment journey smooth sailing every time.