To guarantee safety, regularly inspect your pumps, heaters, ladders, and slides for signs of wear or damage. Check filters and wiring for cleanliness and secure connections, and look for rust, cracks, or loose hardware on ladders and slides. Address any issues immediately to prevent accidents or equipment failure. Keeping detailed records helps track maintenance efforts. Stay proactive; continuing will guide you on more detailed steps to keep everything safe and in top condition.

Key Takeaways

- Regularly check and clean filters on pumps and heaters to prevent overheating and mechanical failure.

- Inspect electrical wiring for frays, loose connections, and corrosion; ensure panels are secure and debris-free.

- Examine ladders for sturdy, rust-free rungs, and ensure side rails are straight and locking mechanisms work properly.

- Inspect slides for cracks, sharp edges, deterioration, and ensure slip-resistant, clean surfaces are maintained.

- Document all inspections and repairs to track maintenance history and ensure compliance with safety standards.

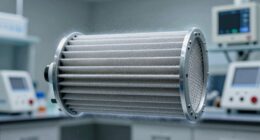

Ensuring the safety of pumps, heaters, ladders, and slides is essential to prevent accidents and protect users. Regular inspections help identify potential hazards before they cause harm. When it comes to pumps and heaters, one of the most critical aspects is proper filter maintenance. Clean filters ensure that equipment runs efficiently and reduces the risk of overheating or mechanical failure. Dirty or clogged filters can cause pumps to work harder, increasing wear and tear, which might lead to leaks or electrical issues. Neglecting filter maintenance can also impair heater performance, leading to uneven heating or even electrical shorts. As part of your inspection routine, make sure filters are clean and replaced regularly according to manufacturer guidelines. This simple step can substantially extend equipment lifespan and enhance safety. Additionally, integrating AI-driven solutions into maintenance routines can help predict failures before they occur, further improving safety and efficiency.

Electrical wiring is another crucial element to scrutinize during safety checks. Faulty or damaged wiring can cause short circuits, sparks, or electrical shocks, posing serious risks. During inspections, look for frayed wires, loose connections, or signs of corrosion. Ensure all wiring is properly insulated and secured, and that electrical panels are closed and free of debris. If you notice any issues, don’t delay in fixing them—call a qualified electrician to handle repairs. Proper wiring not only prevents accidents but also ensures that pumps and heaters operate reliably, maintaining safe water temperatures and consistent performance.

Ladders and slides require their own set of safety checks. For ladders, verify that rungs are sturdy, free of rust or splinters, and that the side rails are straight. Make sure locking mechanisms are functioning correctly. Slides should be examined for cracks, sharp edges, or any signs of deterioration that could cause cuts or falls. Ensure the surfaces are slip-resistant and clean, especially after storms or heavy use. Regularly tighten bolts and screws on these structures to prevent wobbling or collapse. Remember, safety is about proactive maintenance—addressing minor issues early keeps everyone safe and minimizes costly repairs down the line.

Finally, always document your inspections and any repairs made. Keeping a detailed record helps track maintenance history and can be crucial if an incident occurs. Routine checks on filters, electrical wiring, ladders, and slides form the backbone of a safe, reliable recreational or industrial environment. Taking these steps seriously ensures that everyone using the equipment stays safe and that you comply with safety standards and regulations.

Frequently Asked Questions

How Often Should Safety Inspections Be Conducted for These Equipment?

You should conduct safety inspections for pumps, heaters, ladders, and slides regularly, ideally following a strict inspection schedule. Check these items at least once a month, and more often if they experience heavy use or harsh conditions. Use a detailed maintenance checklist during each inspection to identify potential hazards early. Regular inspections help ensure safety and compliance, preventing accidents and costly repairs down the line.

What Specific Tools Are Best for Inspecting Pumps and Heaters?

Think of your inspection tools as the compass guiding you through safety’s labyrinth. For pumps and heaters, use a multimeter to check electrical connections and a bore scope for internal inspections. An inspection checklist ensures you don’t miss critical points, while tool calibration guarantees accuracy. Keep your instruments precise and your assessments sharp, so you can uncover hidden flaws before they become hazards, safeguarding everyone’s safety with confident, informed decisions.

Are There Industry Standards or Regulations for Pool Slide Safety?

Yes, industry standards and regulations guide pool slide safety, emphasizing proper pool slide design and slide impact testing. You should guarantee the slide meets safety codes like ASTM F2375 and comply with local regulations. Regularly evaluate the slide’s design for stability and safety features, and perform impact testing to prevent injuries. Following these standards helps you maintain a safe environment and minimizes liability.

How Can I Identify Early Signs of Equipment Wear or Damage?

Think of your equipment as a trusted vessel on a voyage. To spot early signs of wear, look for equipment corrosion like rust or discoloration, and perform leak detection around seals and joints. These are your early warning signals, indicating potential damage. Regularly inspect for unusual noises or vibrations, and address issues promptly to prevent costly failures. Staying vigilant keeps your pool safe and your equipment seaworthy.

What Training Is Recommended for Staff Performing Safety Inspections?

You should complete thorough training in pool safety signage and emergency response planning. This guarantees your staff can recognize hazards, use safety signs correctly, and respond swiftly to emergencies. Regular workshops and certification courses help reinforce protocols, making safety inspections effective. By staying updated on best practices, you improve overall safety, prevent accidents, and ensure your team is prepared to handle any situation confidently and efficiently.

Conclusion

By regularly inspecting your pumps, heaters, ladders, and slides, you’re the shield that keeps everyone safe. Think of these checks as the heartbeat of your safety routine—without them, the whole system falters. Stay vigilant and proactive, catching issues before they become hazards. Remember, safety isn’t just a duty; it’s the sturdy safety net that catches everyone when accidents try to fall. Keep up the inspections, and guarantee your playground remains a secure haven for all.