Vacuum belts come in various types, including rubber, neoprene, microfiber, and reinforced options, each suited for different tasks and durability needs. Flat belts and V-belts are common, with specialty belts designed for pet hair or heavy-duty cleaning. Ensuring the right belt size, shape, and material is essential for peak performance. If your vacuum struggles or noises persist, a belt replacement might help—discover more ways to keep it running smoothly.

Key Takeaways

- Rubber belts are flexible and provide excellent grip, ideal for daily vacuum use.

- Neoprene belts resist wear and tear, offering longer lifespan and durability.

- Microfiber belts combine strength and flexibility, reducing the risk of snapping.

- Reinforced belts resist stretching and tearing, suitable for heavy-duty cleaning tasks.

- Proper belt selection and maintenance extend vacuum lifespan and ensure optimal cleaning performance.

The Different Materials Used in Vacuum Belts

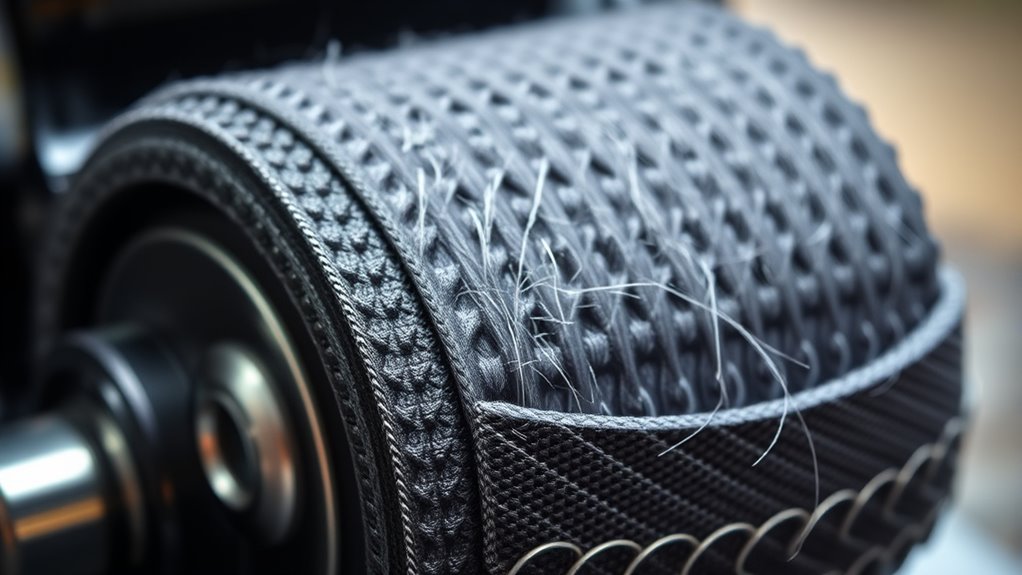

Have you ever wondered what materials make vacuum belts effective and durable? The belt material plays a vital role in how well your vacuum performs and how long it lasts. Common materials include rubber, neoprene, and microfiber, each offering different durability factors. Rubber belts are flexible and provide excellent grip, making them reliable for everyday use. Neoprene belts are resistant to wear and tear, adding to their longevity. Microfiber belts combine strength with flexibility, reducing the risk of snapping. Your choice of belt material affects how well your vacuum can handle debris and how often you’ll need replacements. Understanding these materials helps you recognize what features contribute to a resilient, high-performing vacuum belt, ensuring your appliance runs smoothly for years. Additionally, selecting the right belt material can extend the overall lifespan of your vacuum and improve its cleaning efficiency by reducing the need for frequent replacements.

How to Identify the Right Belt for Your Vacuum Model

To find the right belt for your vacuum, start by checking your model’s compatibility and reading your user manual. Measure the belt size accurately to guarantee a proper fit, and look at the existing belt to identify its type. These steps help you select a replacement that works efficiently and lasts longer. Additionally, consider the maintenance requirements of different belt types to ensure optimal performance over time.

Model Compatibility Tips

Determining the right vacuum belt for your model is essential for peak performance. Check your vacuum’s model number and manufacturer specifications to guarantee compatibility. Using the correct belt safeguards motor safety by preventing strain or damage caused by improper fit. It also helps maintain battery efficiency, as an incompatible belt can cause the motor to work harder, draining power faster. Always verify the belt type—whether it’s a flat, cogged, or round belt—that matches your vacuum’s design. Refer to your user manual or contact the manufacturer when in doubt. Avoid generic or incorrect belts, as they may compromise functionality and cause costly repairs. The right belt ensures your vacuum operates smoothly, protects your motor, and keeps your cleaning routine efficient. Additionally, understanding belt types helps in selecting the most durable and compatible option for your specific vacuum model.

Belt Size Measurement

How can you make certain you get the right belt size for your vacuum? The key is accurate measurement techniques. First, turn off your vacuum and remove the belt. Then, measure its length and width carefully with a ruler or tape measure. Use this chart to compare your measurements:

| Belt Size | Measurement (in inches) | Notes |

|---|---|---|

| Small | 12-14 | For compact models |

| Medium | 14-16 | Standard size |

| Large | 16-18 | Heavy-duty vacuums |

Knowing your belt size ensures a proper fit, preventing slips or motor strain. Always double-check measurements before purchasing a replacement to avoid errors and ensure your vacuum runs smoothly. Additionally, understanding Mazda Tuning concepts can help you maintain or upgrade your vacuum or floor care equipment for optimal performance.

Identifying Belt Type

Ever wonder how to identify the right belt for your vacuum model? First, check the belt tension—if the belt feels loose or slips easily, you might need a different type. Next, look at the belt color; manufacturers often use specific colors to indicate different belt types or sizes. For example, a black belt might be a standard rubber belt, while a clear or colored belt could be a specialty or high-tension type. Always compare the belt’s shape and grooves to your original, as these details ensure compatibility. Remove the belt carefully and examine its markings or numbers. By paying attention to belt tension and color, you’ll accurately identify the right belt, ensuring ideal performance and longevity for your vacuum. Additionally, consulting the manufacturer’s guidelines can provide valuable information on proper belt selection and maintenance.

Flat Belts vs. V-Belts: Which Is Better for Your Floors?

When choosing between flat belts and V-belts for your floors, it’s important to contemplate how each type interacts with your flooring surface. Flat belts generally offer better belt durability due to their even surface, which reduces wear over time. They also provide greater material flexibility, allowing them to adapt smoothly to different pulley sizes without slipping. V-belts, on the other hand, are designed for high-torque applications and often have a more aggressive grip, but they can be less gentle on delicate floors. If your priority is gentle, consistent cleaning without risking damage, flat belts are usually the better choice. Additionally, seasonal variations can influence the performance and selection of belts, especially in outdoor or fluctuating environments. Ultimately, consider your flooring type and cleaning needs to decide which belt type offers the best balance of durability and flexibility for your vacuum.

The Role of Reinforced Belts in Durability and Performance

Reinforced belts markedly boost the durability and performance of your vacuum by resisting stretching, tearing, and wear over time. This belt reinforcement provides a durability enhancement, ensuring the belt maintains tension and efficiency during use. With a reinforced belt, you’re less likely to experience breakdowns or frequent replacements, saving you time and money. The added strength helps your vacuum handle tougher debris and extended cleaning sessions without slipping or losing power.

| Feature | Benefit |

|---|---|

| Belt Reinforcement | Increased resistance to tearing and stretching |

| Durability Boost | Longer-lasting performance |

| Tension Retention | Maintains effective drive over time |

| Wear Resistance | Handles heavy-duty cleaning tasks |

| Cost Efficiency | Reduces replacement needs |

Specialty Belts for Pet Hair and Heavy-Duty Cleaning

Specialty belts designed for pet hair and heavy-duty cleaning are engineered to handle tough debris that standard belts may struggle with. These belts are ideal for cleaning schedules that involve frequent use on pet hair, stubborn dirt, and larger debris. Their durability guarantees consistent performance during demanding tasks, reducing downtime. To keep them in top shape, consider proper storage solutions—store belts in a cool, dry place away from direct sunlight to prevent deterioration. Having a dedicated spot makes it easier to swap belts quickly, especially when tackling heavy-duty jobs or pet-related messes. Investing in these specialty belts can extend your vacuum’s lifespan and improve overall cleaning efficiency, making your floor care routine smoother and more effective. Additionally, selecting belts with appropriate performance metrics ensures optimal suction and cleaning results.

Signs That Indicate Your Vacuum Belt Needs Replacing

If your vacuum isn’t performing as well as it used to, it might be time to check the belt. You may notice a drop in suction power, strange noises during operation, or visible signs of damage on the belt itself. Recognizing these signs early can help you know when it’s time for a replacement. Additionally, if the vacuum’s brush roll isn’t spinning properly, it could indicate a worn or broken vacuum belt, which is essential for proper cleaning performance.

Loss of Suction Power

Noticing a sudden drop in your vacuum’s suction power is often a clear sign that something’s wrong with the belt. When the belt isn’t functioning properly, your vacuum can’t generate enough suction. Here are four signs to watch for:

- Reduced airflow or weak suction during use

- The brush roll isn’t spinning or moving slowly

- Visible wear or cracks on the belt

- Unusual belt slipping or slipping sounds

To fix this, start with belt lubrication if applicable, and check your cleaning techniques to guarantee no debris is causing belt slippage. Regularly inspecting and replacing the belt helps maintain ideal suction power and prevents further damage. If these signs persist, replacing the belt is your best bet. Additionally, understanding the importance of Glycolic Acid benefits for skin can help you recognize similar signs of deterioration in your vacuum’s components over time.

Unusual Noises During Use

Unusual noises during vacuum use often point to issues with the belt. If you notice squealing or screeching sounds, it may indicate that the belt tension is too loose or too tight, affecting smooth operation. These noises can also result from the belt slipping or rubbing against other parts, which compromises noise reduction. When the belt wears out or loses proper tension, it can create a high-pitched sound as it struggles to move the brush roll efficiently. Addressing these noises early helps prevent further damage and ensures your vacuum operates quietly. Check the belt’s tension and adjust or replace it if needed. Proper belt tension not only reduces noise but also extends the life of your vacuum’s components. Regularly inspecting your vacuum’s belt types can help identify issues before they become major problems.

Belt Visible Damage

Are you seeing visible signs of wear on your vacuum belt? If so, it’s time to take action. Here are four key indicators that your vacuum belt needs replacing:

- Belt visible damage, such as fraying or thinning.

- Vacuum belt cracks that run along its length.

- Slipping or belt slipping off the motor shaft.

- Reduced suction or poor brush roll performance.

Belt visible damage and cracks weaken the belt’s integrity, causing it to break or slip. Ignoring these signs can lead to further damage and decreased cleaning efficiency. Regularly inspect your vacuum belt for these signs, and replace it promptly to keep your vacuum operating smoothly. A damaged belt not only hampers performance but can also cause additional wear on other components.

Compatibility Considerations for Universal vs. Brand-Specific Belts

When choosing between universal and brand-specific vacuum belts, understanding their compatibility is vital to guarantee proper function and avoid damage. The belt material plays a key role, as some universal belts may use different materials that wear out faster or don’t grip as well. Brand-specific belts are designed to match the exact specifications of your vacuum, ensuring peak performance. Additionally, brand compatibility ensures that the belt fits securely and works smoothly with your machine’s pulleys and brush rolls. Using an incompatible belt, even if it looks similar, can cause slipping, noise, or damage to your vacuum components. Always check your vacuum’s model and manufacturer recommendations before selecting a belt to guarantee compatibility and longevity.

Tips for Installing and Maintaining Your Vacuum Belts

Proper installation and regular maintenance are key to guaranteeing your vacuum belts perform effectively and last longer. When doing belt installation, always turn off your vacuum and unplug it first. Follow these maintenance tips for peak performance:

Proper installation and maintenance ensure vacuum belt performance and longevity.

- Check for wear or cracks regularly and replace belts when needed.

- Ensure the belt fits snugly but isn’t too tight, preventing strain on the motor.

- Clean the brush roll and pulley area to prevent debris buildup that can cause slipping.

- Rotate or replace belts every 6-12 months, depending on usage, to avoid unexpected breakdowns.

Frequently Asked Questions

Can Vacuum Belts Be Repaired Instead of Replaced?

You can often do belt repair if the belt is just stretched or slightly frayed, but most issues require belt replacement. If the belt is broken or severely worn, replacing it is the best option for maximum performance. Carefully inspect your vacuum’s belt; if it’s in good shape, try belt repair, but don’t hesitate to replace it if damage is significant to ensure your vacuum works efficiently.

How Often Should I Check My Vacuum Belt for Wear?

Think of your vacuum belt as the heartbeat of your cleaner—keep an eye on it. You should check your belt inspection every 3-6 months, or sooner if you notice decreased suction or unusual noise. Regular replacement frequency depends on usage, but generally, belts last about 6-12 months. Staying vigilant helps prevent unexpected breakdowns and keeps your vacuum performing at its best.

Are There Eco-Friendly Options for Vacuum Belts?

Yes, you can find eco-friendly vacuum belts made from sustainable materials and biodegradable options. Look for brands that prioritize environmentally conscious manufacturing, as they often use natural rubber or recycled components. These belts perform just as well as traditional ones while reducing environmental impact. Switching to biodegradable options helps you care for your home and the planet, making your cleaning routine more sustainable without sacrificing effectiveness.

Do Different Flooring Types Require Specific Belt Types?

Yes, different flooring types require specific belt types due to flooring compatibility and belt material. For example, thick carpets need durable belts that can handle extra tension, while hardwood floors require gentler belts to prevent damage. Always check your vacuum’s manual for the recommended belt material and compatibility, ensuring peak performance and preventing wear. Using the right belt for your flooring type keeps your vacuum running smoothly and extends its lifespan.

What Safety Precautions Should I Take When Replacing a Belt?

Replacing a vacuum belt is like handling a delicate flower—you need to be gentle and precise. Always unplug your vacuum first to guarantee belt safety. Use the correct replacement tools, such as screwdrivers, to avoid damage. Wear gloves if needed to protect your hands, and handle the belt carefully to prevent stretching or tearing. Following these precautions keeps you safe and ensures your vacuum runs smoothly after the replacement.

Conclusion

So, next time your vacuum refuses to cooperate, don’t blame the dog or your cleaning skills. Maybe it’s just crying out for a new belt—because nothing says “luxury” like a squeaky, slipping drive. With the right belt, your floors will shine, and your patience will remain intact. Remember, in the world of vacuum belts, a little upgrade can turn a chore into a breeze—who knew? Happy cleaning!