To create an effective multistage filtration system, start by testing your water or air quality to identify contaminants. Then, design your system based on those needs, selecting compatible filters and media for each stage. Prepare your workspace with the necessary tools, carefully install and calibrate each filter, and perform initial checks for leaks or pressure issues. Ongoing maintenance, monitoring, and adjustments are key, ensuring your system stays efficient—continue to explore each step for a successful setup.

Key Takeaways

- Assess water or air quality through testing to identify contaminants and define filtration goals.

- Design the filtration system by selecting suitable stages, media, and ensuring component compatibility.

- Choose appropriate filters and media based on targeted pollutants and system requirements.

- Follow proper installation, calibration, and leak testing procedures to ensure optimal operation.

- Establish maintenance schedules, monitor system performance, and keep the workspace organized for efficiency.

Top picks for "complete checklist multistage"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

Assess Your Water or Air Quality Needs

Before choosing a filtration system, you need to understand your specific water or air quality needs. Start with water testing to identify contaminants like lead, chlorine, or bacteria that may be present. For air, conduct an air analysis to detect pollutants such as dust, pollen, or volatile organic compounds (VOCs). Knowing these details helps determine what type of filtration is necessary, whether it’s removing chemicals, particulates, or biological impurities. Accurate testing provides a clear picture of your environment’s quality, guiding you in selecting the right system. Don’t skip this step—rushing into filtration without understanding your needs could lead to ineffective results or unnecessary expenses. Taking the time for thorough water testing and air analysis ensures your filtration system will be tailored for optimal performance filtration technology.

Design Your Multistage Filtration System

To design your multistage filtration system, start by evaluating your water quality needs to identify which contaminants to target. Next, determine the ideal sequence of stages to guarantee effective filtration. Finally, select filters that match each stage’s specific requirements for a reliable and efficient setup. Incorporating appropriate filtration materials tailored to your water’s unique characteristics can enhance overall performance and longevity of the system.

Assess Water Quality Needs

How do you determine the specific contaminants present in your water? The first step is conducting water testing, which provides vital data for contaminant analysis. You’ll need to identify pollutants such as bacteria, heavy metals, chemicals, or sediments that affect water quality. Accurate testing helps you understand what needs removal and guides your filtration system design. Use certified laboratories or at-home test kits to gather reliable results. Once you know the contaminants, you can select appropriate filtration stages tailored to your water’s unique needs. Skipping this step risks installing ineffective filters or overlooking harmful substances. By evaluating your water quality thoroughly, you ensure your multistage filtration system targets all contaminants efficiently, protecting your health and optimizing system performance. Proper testing also helps you determine the types of filters necessary for your specific water conditions.

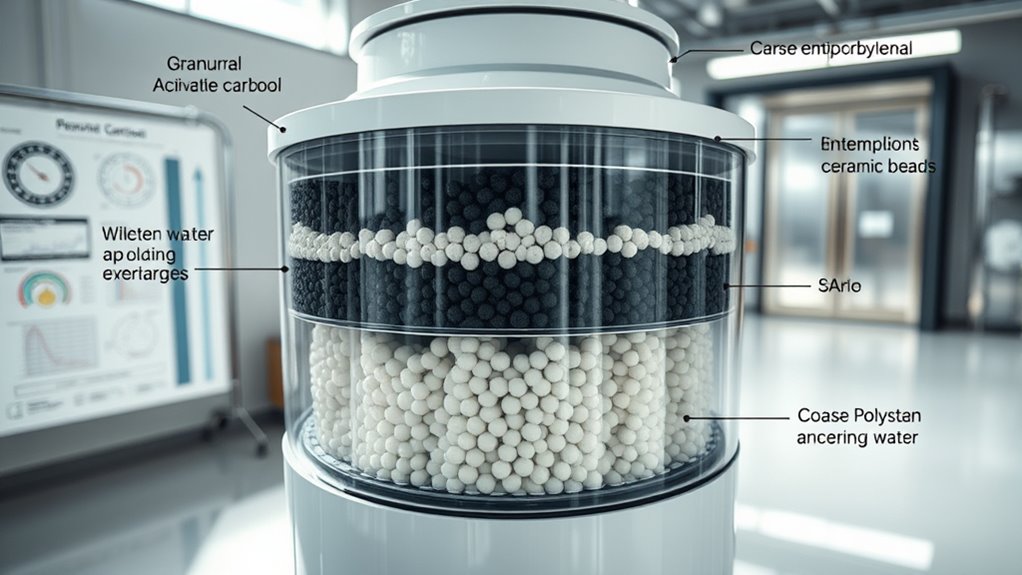

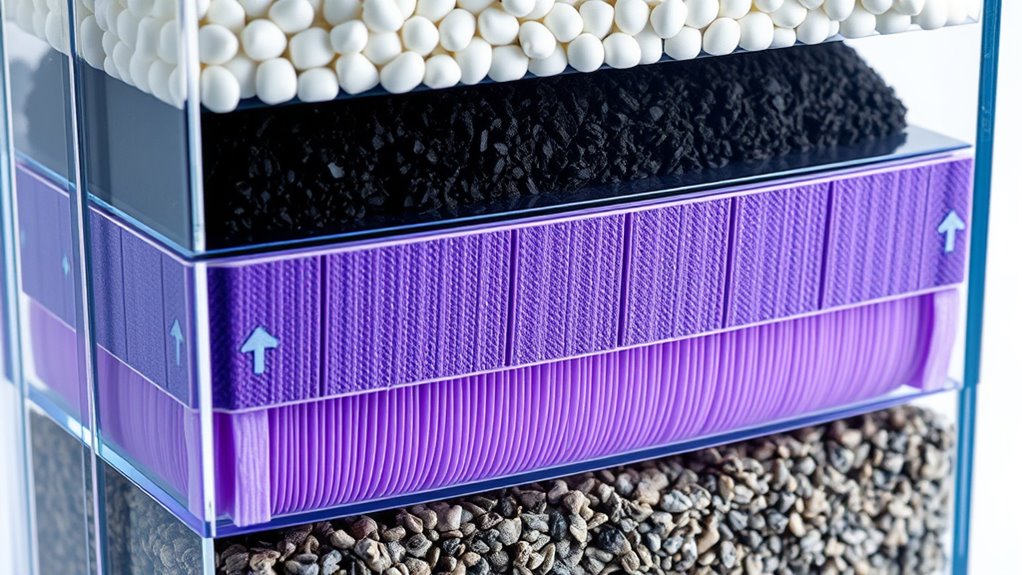

Determine Stage Sequence

Once you’ve identified the contaminants in your water, the next step is to determine the most suitable sequence of filtration stages. Filter stage sequencing is vital because it ensures contaminants are removed efficiently and prevents clogging or damage to filters. To develop an effective process flow arrangement, start with pre-filtration to eliminate larger particles, followed by stages targeting specific contaminants like chemicals or microorganisms. Consider the order carefully; often, physical filters come first, then chemical treatments. This sequencing optimizes flow and prolongs filter lifespan. Additionally, understanding air purifier technologies can help you select appropriate filters for each stage, ensuring optimal performance and longevity. By planning your process flow arrangement thoughtfully, you’ll create a system that maximizes filtration performance while maintaining operational simplicity. Proper stage sequencing is the backbone of a reliable, effective multistage filtration system.

Select Appropriate Filters

Choosing the right filters is essential for guaranteeing your multistage filtration system works effectively. You need to select filter materials that match your water quality goals, balancing filtration efficiency with flow rate. Consider the specific contaminants you want to remove, such as sediments, chemicals, or bacteria, and choose filters designed for those purposes. Here’s a quick guide:

| Filter Material | Filtration Efficiency |

|---|---|

| Activated Carbon | Removes chemicals, odors |

| Sediment Filter | Traps particulates, sediments |

| Ultrafine Membranes | Eliminates bacteria, viruses |

Matching filter materials with your targets ensures excellent performance and longevity. Always verify the filtration efficiency levels to achieve your desired water purity. Additionally, understanding the types of yoga can help inform your selection of filtration systems suited for different environments or needs.

Select Appropriate Filtration Media and Components

Choosing the right filtration media and components guarantees your system works efficiently and lasts longer. You need to take into account media compatibility and types to match your water quality needs, while also checking that components are durable enough for your application. Make sure everything aligns with your system design to avoid issues down the line. Additionally, understanding different filtration media types can help optimize your system’s performance and longevity.

Media Compatibility and Types

Selecting the right filtration media is essential to guarantee your system effectively removes contaminants without compromising flow rates or filter lifespan. Understanding media types and media compatibility ensures your filtration stages work seamlessly. Different media serve specific functions, so choosing compatible options prevents clogging and reduces maintenance. Consider these key points:

- Match media types to target contaminants for efficient removal.

- Verify media compatibility with your system’s materials and design.

- Use compatible media to avoid chemical reactions that could damage components.

- Regularly check media specifications to assure they meet your filtration needs.

- Ensuring proper media selection also depends on understanding the contrast ratio, which influences the clarity and overall quality of the filtered output.

Component Durability and Lifespan

To guarantee your filtration system remains effective over time, it’s essential to pick media and components that are durable and have a suitable lifespan. Choosing high-quality materials enhances filter longevity and minimizes component wear, reducing the need for frequent replacements. Look for components designed to withstand operational stresses and chemical exposure, ensuring they stay functional longer. Regularly evaluating the durability of filters and other parts helps prevent breakdowns that can compromise filtration efficiency. Investing in durable components not only extends your system’s lifespan but also maintains consistent performance. Remember, the right materials resist degradation, resist clogging, and support ongoing filtration needs without premature failure or excessive maintenance. Prioritizing component durability is key to a reliable, long-lasting multistage filtration system. Additionally, selecting filters with advanced HEPA filtration technology can further improve efficiency and longevity by effectively capturing small particles and allergens.

Compatibility With System Design

Guaranteeing your filtration media and components are compatible with your system design is essential for peak performance. If the filter material doesn’t match your system’s specifications, you risk inefficiency or damage. To achieve ideal system compatibility, consider these points:

- Verify the filter material’s pore size aligns with your filtration goals.

- Confirm the filter dimensions fit seamlessly into your existing system.

- Ensure the pressure ratings of components match system operating conditions.

- Choose components that are compatible with your system’s flow rate and capacity.

- Regularly assess and adjust your system setup to maintain optimal system performance.

Prepare Your Workspace and Gather Tools

Before starting your multistage filtration process, it’s essential to set up a clean and organized workspace. Confirm your area is free of clutter to promote lab safety and prevent contamination. Gather all necessary tools beforehand—filter housings, tubing, clamps, and replacement filters—so you don’t waste time searching during the setup. Keep cleaning supplies nearby to maintain hygiene and quickly disinfect surfaces if needed. Check that your workspace has adequate lighting and ventilation to ensure safe handling of materials. Using a designated, tidy space reduces the risk of accidents and cross-contamination. Making sure everything is in place before you begin helps streamline the process and keeps your workflow efficient and safe. Proper preparation sets the foundation for a successful multistage filtration. Additionally, reviewing installation planning resources can help ensure your setup aligns with best practices for optimal water quality and flow rate.

Install Each Filtration Stage Correctly

Installing each filtration stage correctly is crucial for achieving peak performance and preventing leaks or bypass. Proper filter installation ensures your system runs smoothly and maintains ideal filtration. To do this effectively:

- Confirm the filter orientation matches manufacturer instructions for proper flow.

- Secure each filter tightly without over-tightening to prevent damage.

- Check all connections for leaks before proceeding.

- Perform system calibration after installation to ensure filters function correctly.

- Pay close attention to details during filter installation, as incorrect placement can compromise filtration efficiency. Accurate system calibration aligns flow rates and pressure, maximizing performance. Take your time to double-check each stage and follow manufacturer guidelines carefully. Proper installation and calibration guarantee your multistage filtration system operates at its best, protecting your equipment and maintaining water quality. Proper installation techniques are essential for preventing issues and ensuring long-term system reliability.

Conduct System Testing and Initial Checks

After installing each filtration stage, it’s important to perform thorough system testing and initial checks to verify everything functions properly. Begin by conducting system calibration to ensure filters are correctly aligned and operating at ideal settings. This step helps prevent future issues and guarantees accurate filtration. Next, perform leak testing on all connections, fittings, and housings to identify any potential leaks that could compromise system performance. Check for abnormal pressure drops or unusual noises, which may signal installation errors or component faults. Confirm that flow rates meet specifications and that valves operate smoothly. Additionally, understanding proper disposal practices can help prevent clogs and system malfunctions. Conducting these initial checks promptly ensures your multistage filtration system performs reliably and efficiently from the start, reducing the risk of failures and extending the system’s lifespan.

Establish Maintenance and Replacement Schedules

Establishing a clear maintenance and replacement schedule is essential for ensuring your multistage filtration system remains effective and reliable over time. Regularly scheduling filter replacement prevents clogs and maintains water quality. A well-planned maintenance schedule also prolongs system life and minimizes unexpected breakdowns. To get started: 1. Determine filter replacement intervals based on manufacturer guidelines. 2. Schedule routine inspections to check for wear or damage. 3. Keep a record of maintenance activities and filter replacements. 4. Adjust the schedule as needed based on system performance and water usage. Additionally, understanding filter lifespan can help optimize your maintenance routine and ensure continuous water purification.

Monitor System Performance and Make Adjustments

Monitoring your system’s performance is crucial to guaranteeing it functions at its best over time. Regularly check sensor calibration to confirm your readings remain accurate, as drift can affect filter efficiency. Use data logging tools to track performance metrics such as flow rates, pressure drops, and contaminant levels. Analyzing this data helps identify trends and detect issues early, allowing you to make timely adjustments. If performance declines, consider recalibrating sensors or replacing filters as needed. Keep an eye on system alerts and alarms to promptly address potential problems. Conduct periodic performance assessments to ensure all components operate optimally. Consistent monitoring ensures your multistage filtration operates effectively, prolonging equipment lifespan and maintaining water quality. Make adjustments based on the data you gather, ensuring your system remains reliable and effective.

Frequently Asked Questions

How Often Should I Replace Each Filtration Media?

You should replace each filtration media according to its lifespan and your replacement schedule. Typically, pre-filters last about 1 to 2 months, carbon filters around 6 to 12 months, and sediment filters every 3 to 6 months. Keep an eye on water quality and flow rate, as these indicate when media replacement is needed. Regular maintenance ensures desirable filtration performance and extends your system’s lifespan.

Can I Customize the Filtration Stages for Specific Contaminants?

Yes, you can customize your filtration stages for specific contaminants by exploring various customization options. Focus on selecting filtration media that target your particular contaminants effectively. For example, use activated carbon for chemicals and odors, or reverse osmosis for dissolved solids. Adjusting the stages based on your water quality allows you to optimize contaminant targeting, ensuring your system effectively removes the pollutants you’re most concerned about.

What Safety Precautions Are Recommended During Installation?

During installation, prioritize safety precautions by wearing protective gear like gloves and goggles. Make sure proper site preparation by clearing the area of debris and securing stable footing. Follow manufacturer instructions carefully, and disconnect power sources before starting. Keep a fire extinguisher nearby, and work in well-ventilated areas. Double-check all connections for leaks and secure fittings tightly, minimizing risks and guaranteeing a safe, efficient filtration system setup.

How Do I Troubleshoot Common System Malfunctions?

If your system isn’t performing well, start troubleshooting by checking for clogs or leaks that could affect system efficiency. make certain filters are clean and replace them if necessary. Review your maintenance schedules to confirm regular upkeep. If issues persist, inspect valves and connections for damage. Regular maintenance helps prevent malfunctions, so sticking to your schedule keeps your multistage filtration system running smoothly and efficiently.

Are There Eco-Friendly Options for Filtration Media?

Think of eco-friendly filtration options as a invigorating gust of fresh air. You can choose biodegradable media that naturally break down, reducing environmental impact, or opt for recycled filtration materials that give new life to waste. These choices help protect our planet while maintaining clean water. Switching to such sustainable media not only benefits the environment but also supports responsible resource use, making your filtration system a champion of eco-consciousness.

Conclusion

Don’t let the complexity of multistage filtration discourage you. With this checklist, you can confidently design and maintain an effective system tailored to your needs. Remember, regular monitoring and timely replacements ensure peak performance and longevity. Investing a little effort now saves you from costly repairs or ineffective filtration later. Embrace the process, and you’ll enjoy cleaner water or air, knowing you’ve taken control of your environment with a proven, step-by-step approach.